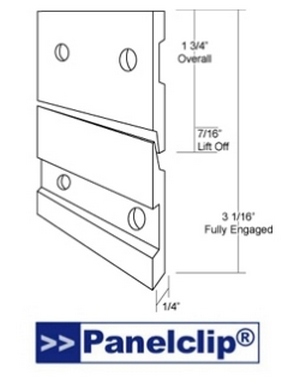

Stonewood Exposed Fastener (EF) Overview

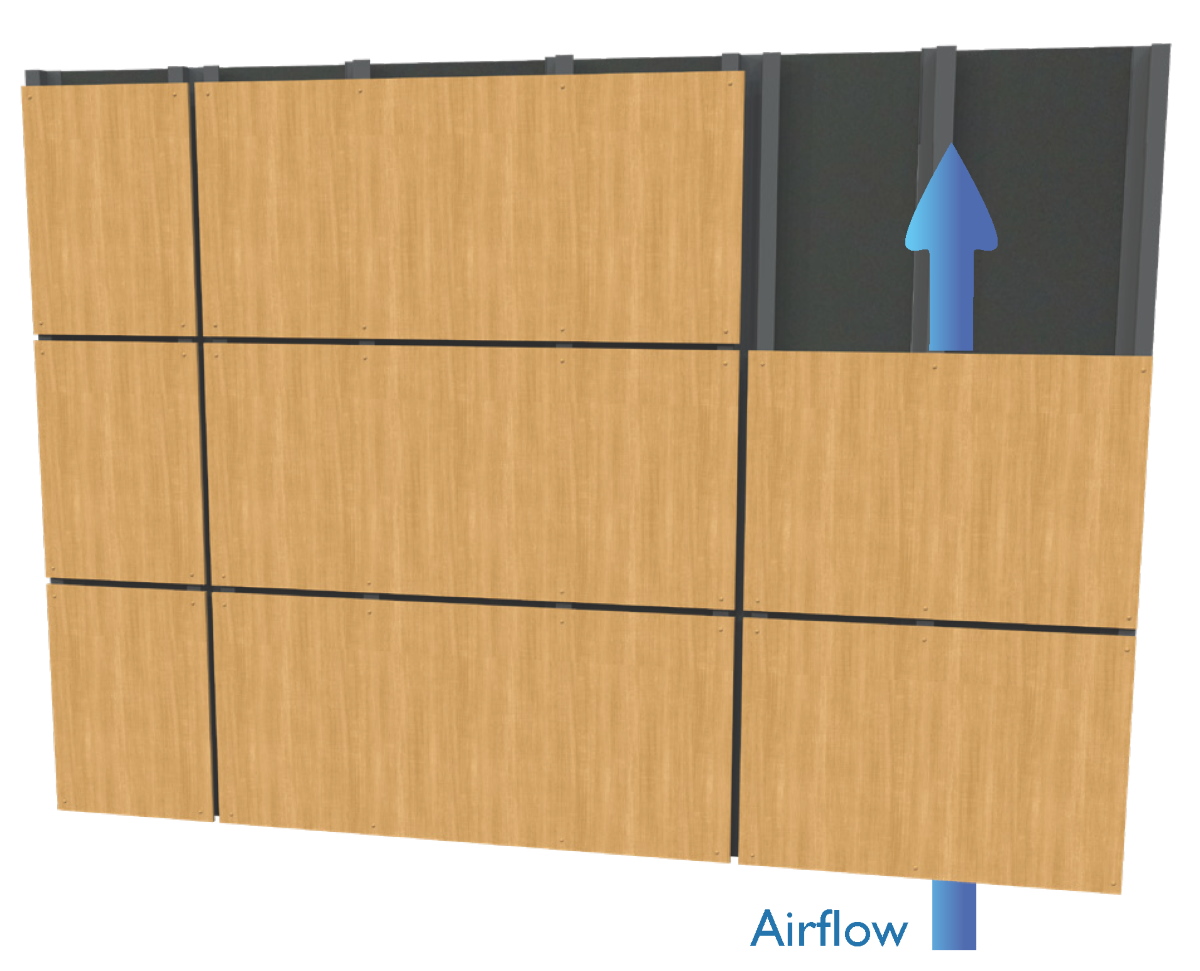

Solid phenolic core panels and exposed fastener system for use as open joint exterior cladding in a ventilated facade system. Panels attach to a one inch sub-framing system with exposed fasteners. Stonewood Architectural Panels are required to have unobstructed air flow behind the panels.

Exposed Fastening System Benefits:

- Economical and flexible fastening system.

- Use for all panel sizes.

- Color matching or accent fasteners add design disguise or accent.

- Flexible fabrication either on the job site or in factory.

- Easily adjusts around windows and other building variations.

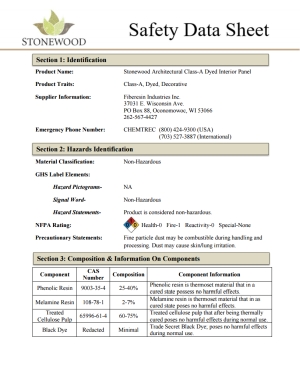

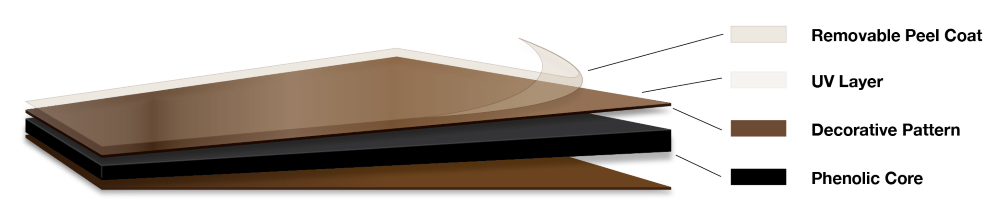

Panel Material Composition

Stonewood is manufactured with a core of phenolic resin impregnated kraft paper and a decorative pattern. These layers are compressed at high pressure and temperature creating a highly durable, non-porous panel. The panel is further safeguarded by a UV-protective layer and a clear peel coat for shipping and handling.

The exposed panel edges and the horizontal reveals —between the panels—are the natural core of the phenolic panel.

As the natural core ages it will develop a patina, turning from dark grey to light grey.

Phenolic Benefits:

- Solid core phenolic panels are strong, highly durable, and impervious to moisture and bacteria.

- Non-porous surface is easy to clean and graffiti resistant.

- UV protective layer filters 99% of damaging UV rays.

- Suited for all construction types and climates.

- Fabricate in the field or factory.

- Self-edging or traditional edge treatments.

- Class A or B fire ratings.

- Optional FSC® (Forest Stewardship Council®) certification (FSC-C115183)

- Made in America

Fabrication

Panels can be both field and factory fabricated.

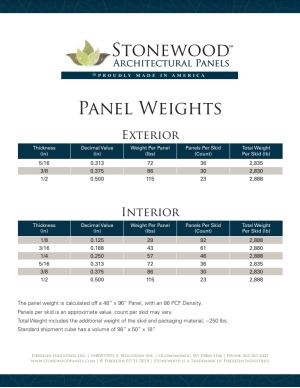

Panel Sizes x 96"L

| Thickness | Panel Size Before Fabrication | Weight |

| 5/16" | 48" x 96" | 72 lbs |

| 3/8" | 48" x 96" | 86 lbs |

| 1/2" | 48" x 96" | 115 lbs |

Design Offering

Over 300 colors are available in wood grains,abstract, and solids. View complete Design Offering and order samples here.

Technical and Environmental

Approvals:

- Passed NFPA 285

- Class A or Class B Fire Rating

- ICC-ES Approval

- Miami-Dade County NOA (Notice of Acceptance)

- Florida Product Approval FL27934

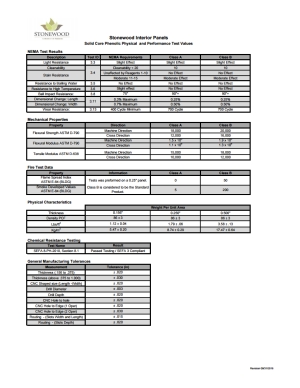

- NEMA Test Results

- ASTM D-790: Flexural Strength, Flexural Modulus

Click here for in-depth testing and report documents.