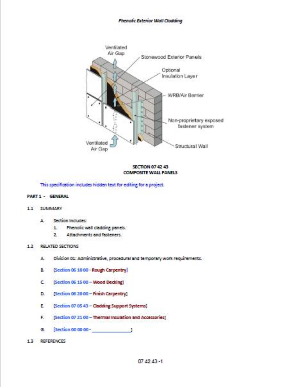

| Exposed Fastener (EF) System Overview |

EF System Benefits

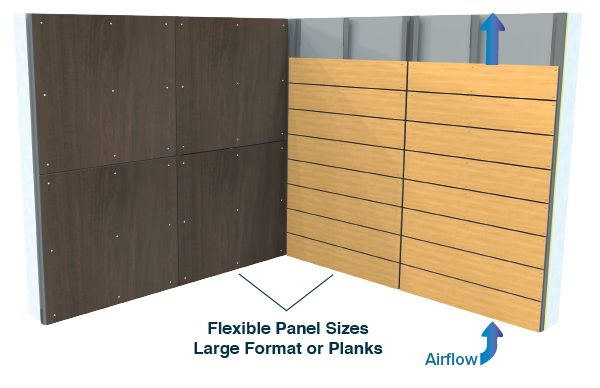

- Simple, economical and flexible fastening system

- Color matching or accent fasteners

- Ideal for large format panels, planks, complex geometry

- Easily adjusts around windows and other complicated geometry

- Factory fabrication to any size, design with 48” x 96” in mind

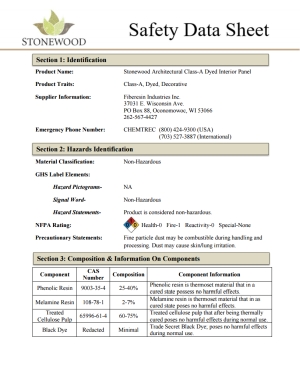

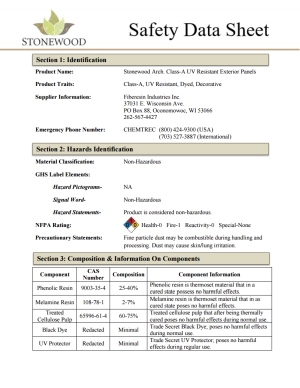

- Three panel types: Class A-285, Class A, Class B

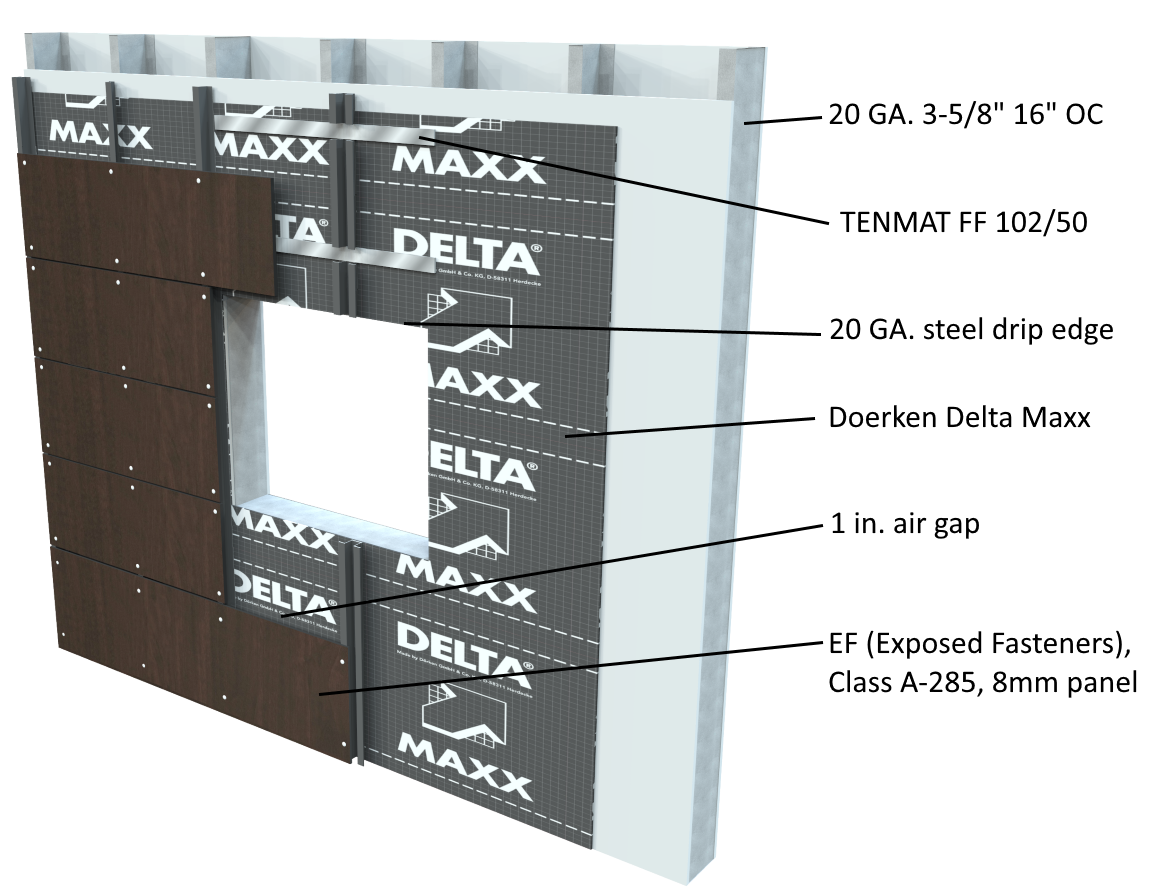

- NFPA 285 compliant assembly using Class A-285 8mm panels

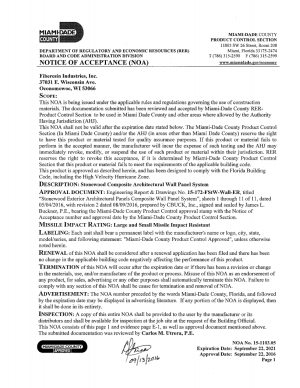

- Exposed Fastening Miami-Dade County NOA#21-0722.02

- Florida Product Approval using Class A 10mm panels, FL27934

- FSC® (FSC-C115183) certification available

|

||

|

|

| Markets We Serve |

|

Architectural Design |

Design Build |

Refresh/Re-Clad |

Preferred Domestic Manufacturer |

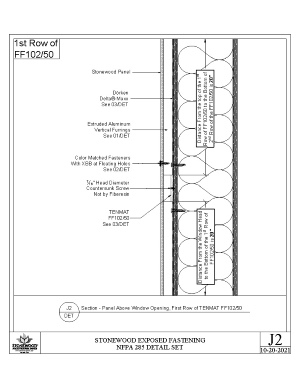

| NFPA 285 Compliance |

Stonewood 8mm, Class A panels attached with the EF system have received compliance certification for NFPA 285 fire test. Learn more about the configuration and details.

| Design Offering |

| EF Panel Sizes |

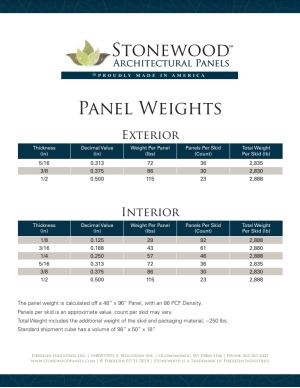

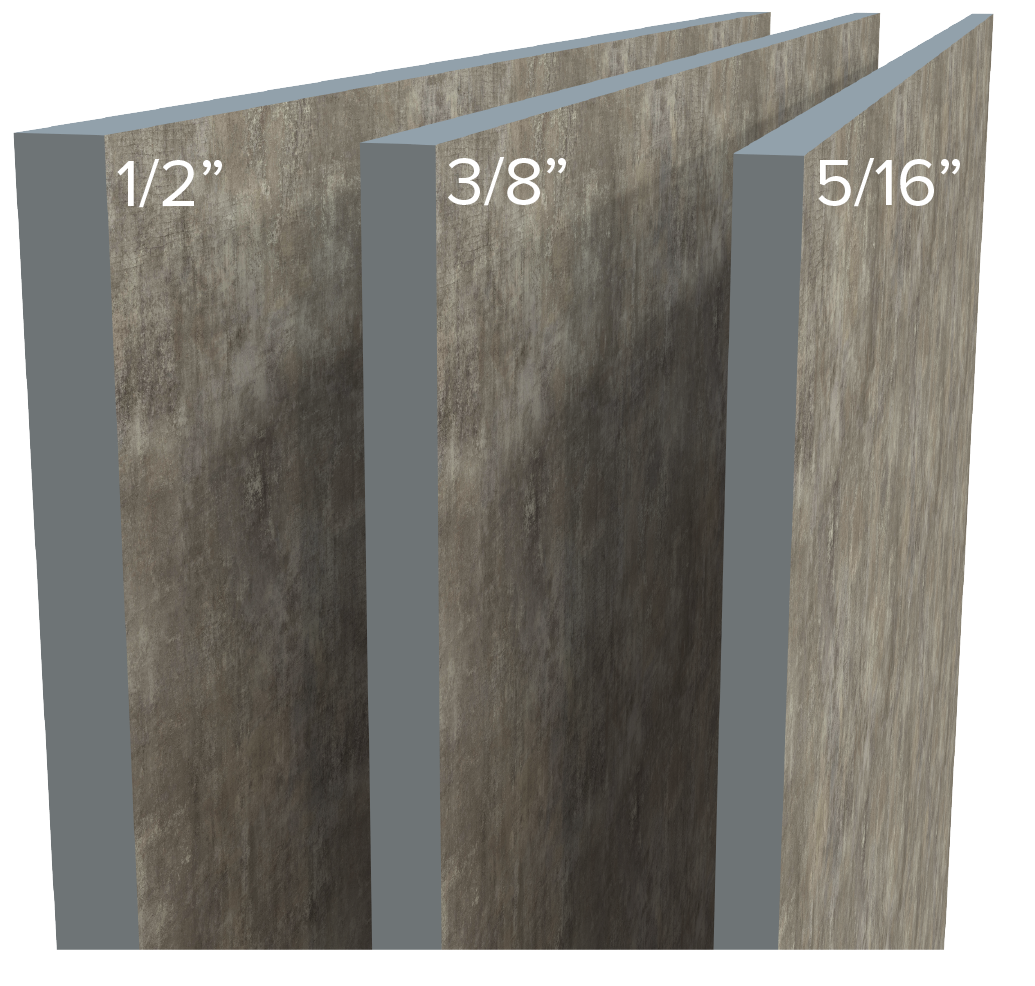

| Thickness | Panel Size Before Fabrication | Weight Per Panel | Weight Per sq.ft. |

| 5/16" | 48" x 96" | 72 lbs | 2.25 lb/sq.ft. |

| 3/8" | 48" x 96" | 86 lbs | 2.69 lb/sq.ft. |

| 1/2" | 48" x 96" | 115 lbs | 3.59 lb/sq.ft. |

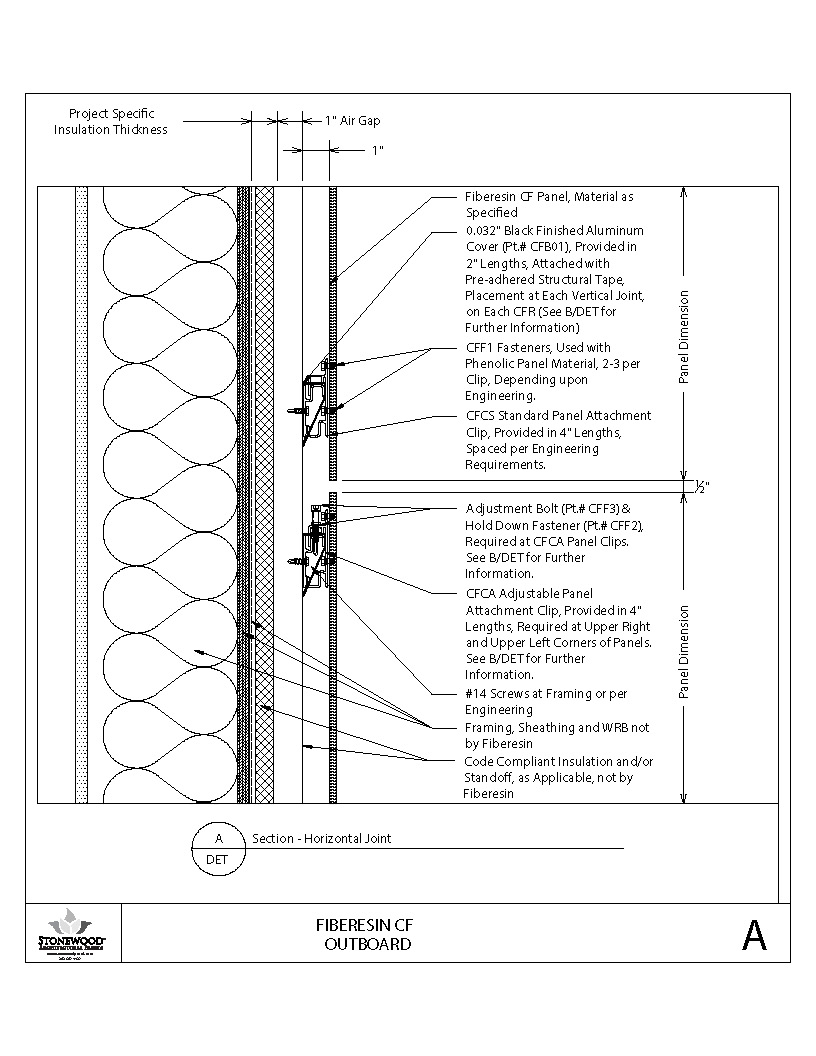

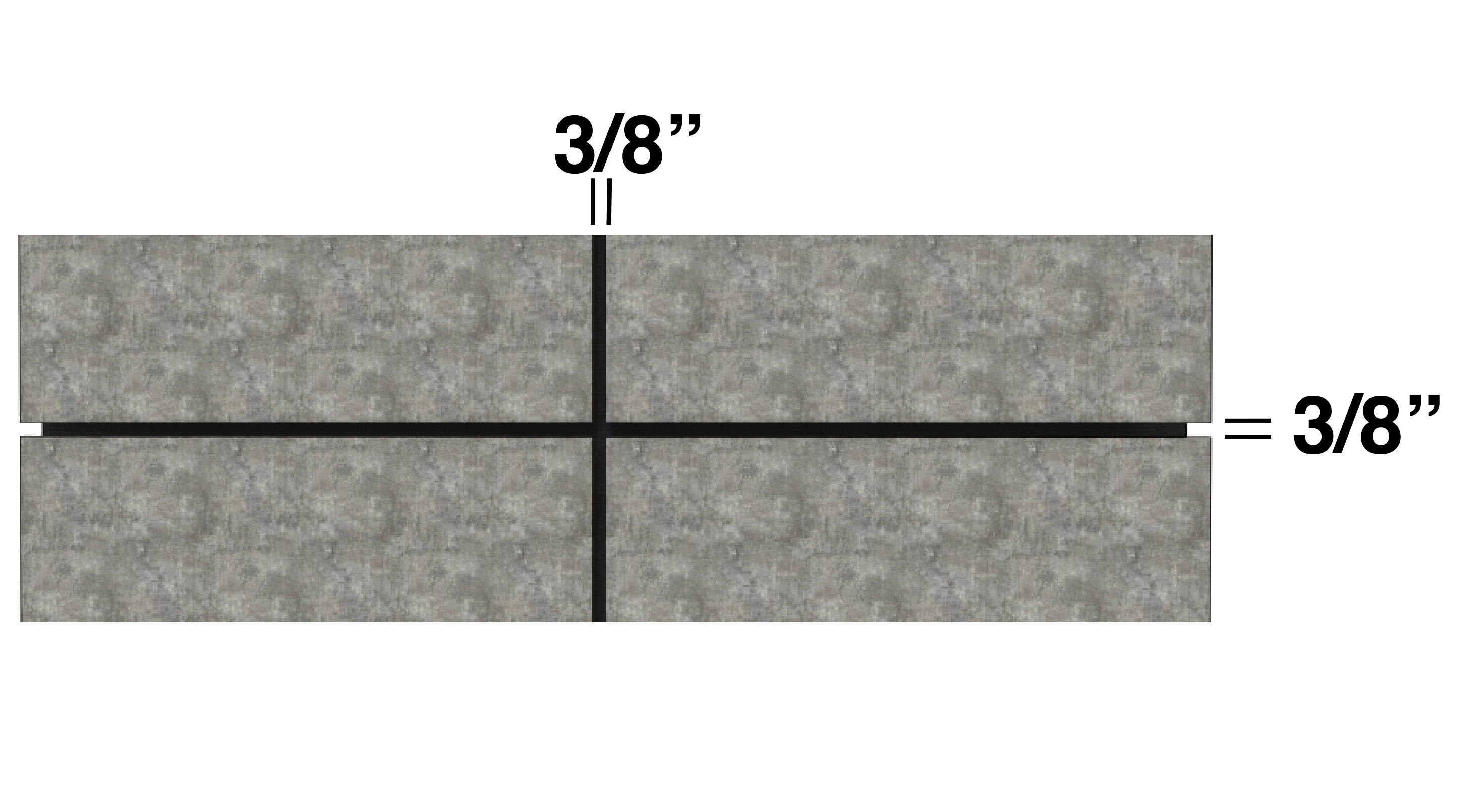

| Panel-To-Panel Joints |

For Exposed (EF) System, a minimum distance of 3/8" must be

maintained between planks to accomodate hygrothermal movement.

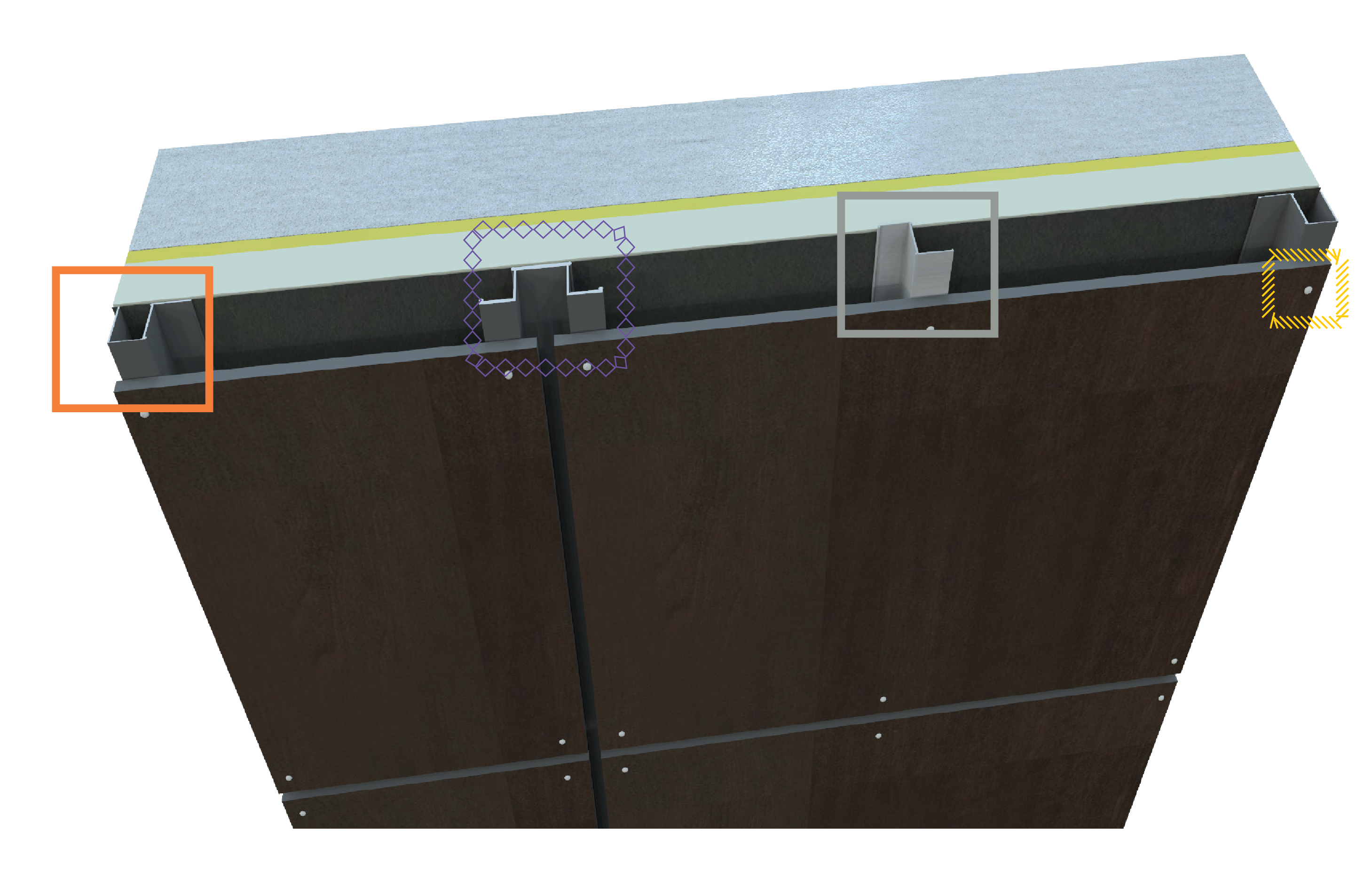

| PARTS OVERVIEW |

|

|

|

|

|

|

|

|

| TECHNICAL RESOURCES |