PDF Download

|

Items discussed in this video are:

- 0:37 Recommended Tools

- 0:45 Pre-Fabrication Setup

- 1:10 General Cutting and Chamfering

- 2:07 Door & Window Detailing

- 2:32 Exposed Fastening Drilling

- 3:18 Concealed Fastening Drilling

- 4:12 Kerfing

- 4:40 Rabbeting

- 5:01 Penetrations

- 5:33 Final Inspection

|

|

Field Kerfing Required Equipment

1. FREUD - 9/16” Depth Slotting Cutter Set (figure a) or equivalent

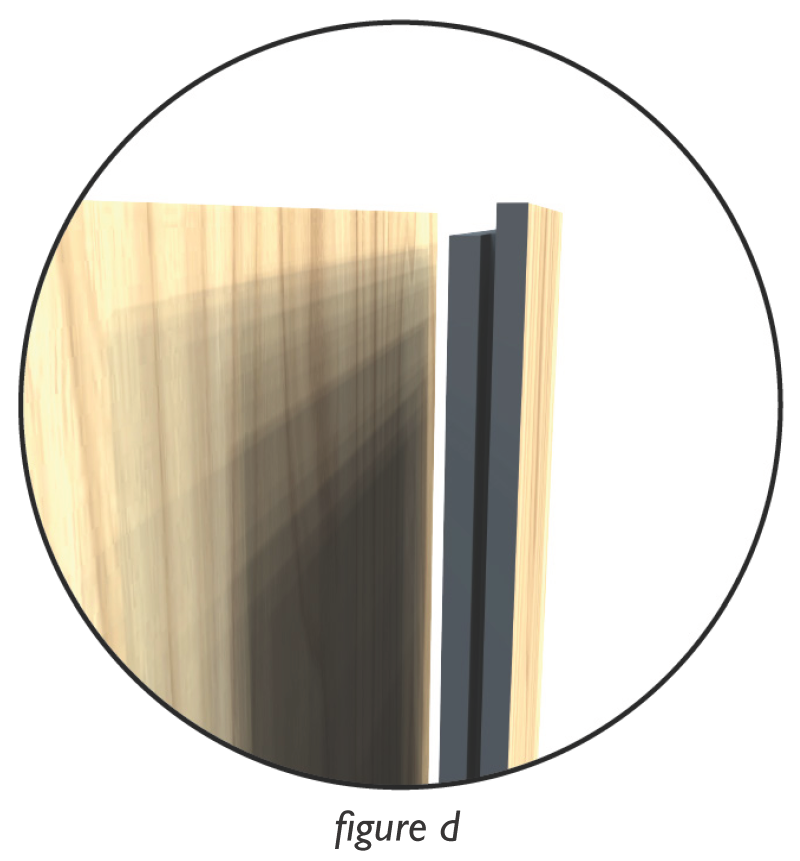

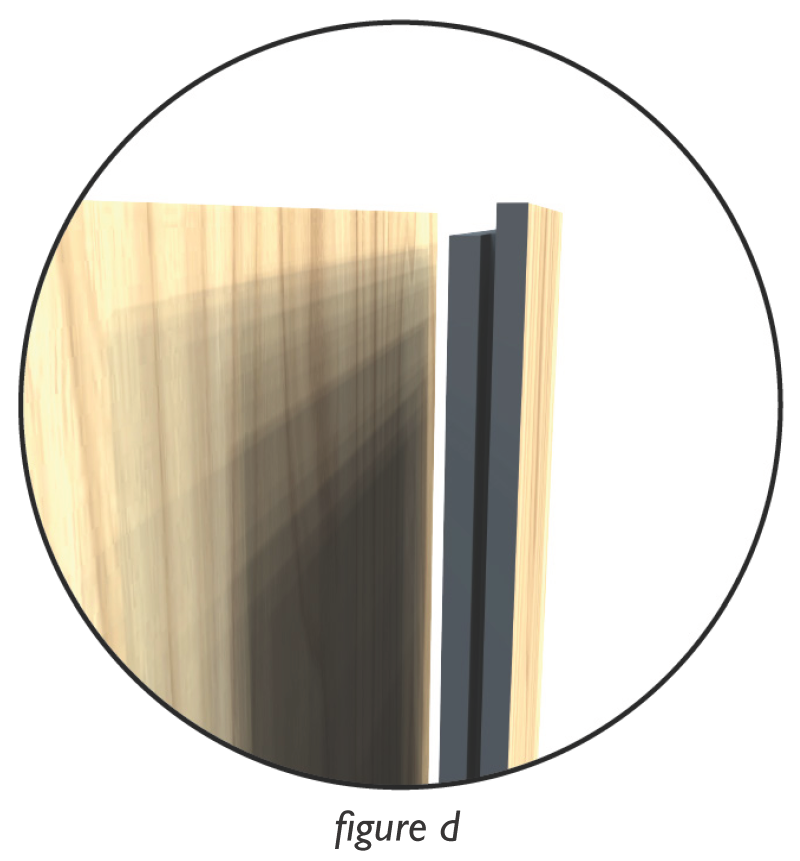

2. Hand Router (figure b) - minimum of 1hp or equivalent tool such as 3 wing slotting cutter (figure c)

|

|

Best Practice Field Kerfing Guidelines

- Insert slotting cutter tool into the hand router

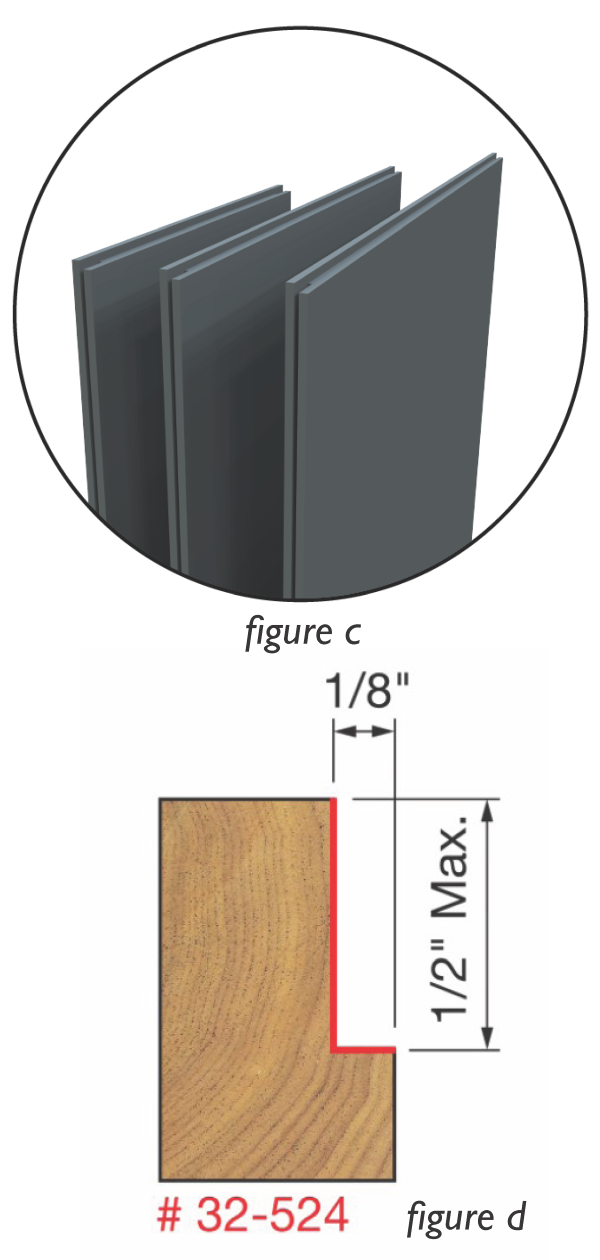

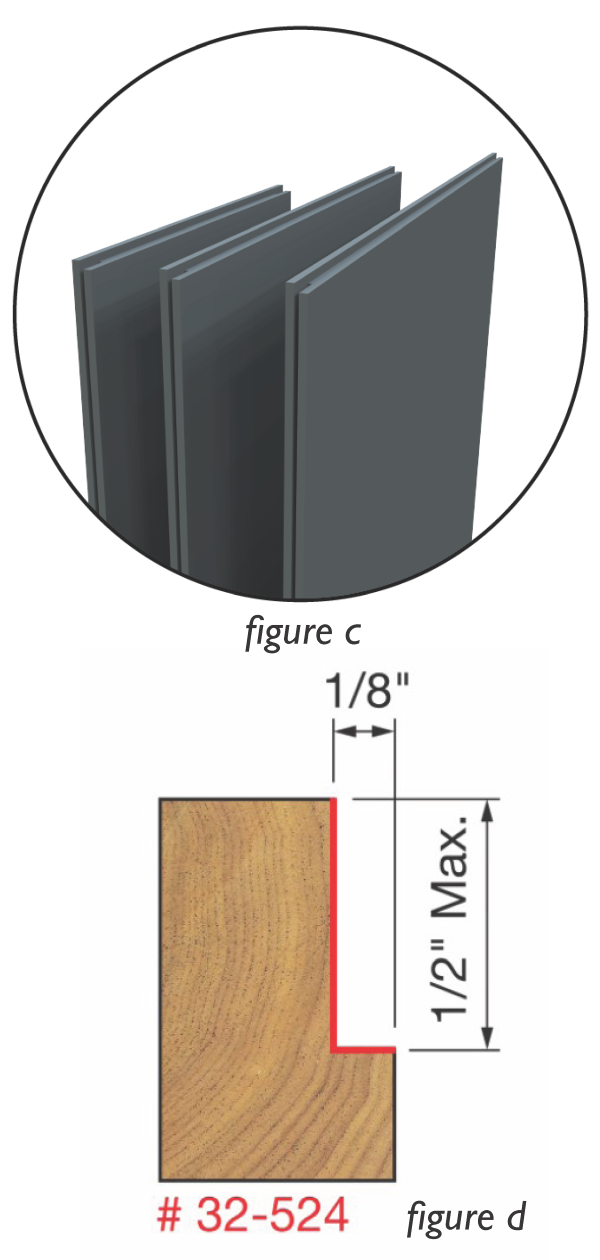

- Use a manufactured kerf plank (figure d) as a set up guide to confirm tool height

- Place the blade in the kerf

- Set tool height

- Perform a test run on a scrap plank

- Speed rate for hand router: 1400-1800 RPMs

- Feed rate for hand router: 8-12 ft/min

- Kerf planks as required

- Maintain tolerances - planks arrive with a .415” kerf and field cut edges must be re-kerfed to 0.500”

|

|

Additional Requirements

1. Minimum width of finished plank is 3”

2. Maximum width of finished plank is 16”

3. Minimum plank length is 4”

Required Equipment Rabbeting

1. FREUD - 1/8”,1/4”, 5/16”, 3/8”, 7/16”, 1/2” Depth Rabbeting Bit Set with interchangable bearings (figure a) with 1/2” Shank or equivalent tool

2. Hand Router (figure b) - minimum of 1hp or equivalent tool

|

|

Best Practice Field Rabbeting Guidelines

- Insert rabbet cutter tool into the hand router

- Use a manufactured rabbet plank (figure c) as a set up guide to confirm tool height

- Use bearing designed to cut a 1/8” depth rabbet (figure d)

- Perform a test run on a scrap plank, once height is set

- Speed rate for hand router:1400-1800 RPMs

- Feed rate for hand router: 8-12 ft/min

- Rabbet as required

- Tolerances - planks will arrive with a 1/8” x 0.157” rabbet cut and the field cut planks must be re-rabbeted to 1/8” x 0.157”

|

|

Additional Requirements

1. Minimum width of finished plank is 3”

2. Maximum width of finished plank is 16”

3. Minimum plank length is 4”