| Exceptional Rainscreen Product |

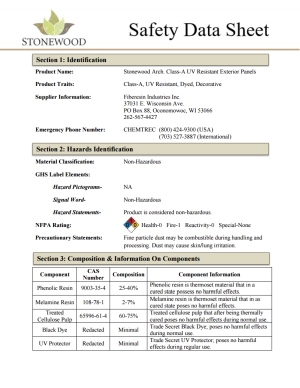

ABET LAMINATI, one of the world's leading manufacturers of decorative laminate, located in Bra, Italy, has completed the acquisition of Fiberesin, maker of Stonewood Architectural Panels. This change enhances the Stonewood offering to include the Italian-made MEG (Material Exterior Grade) Panels and EasyMEG for exterior applications.

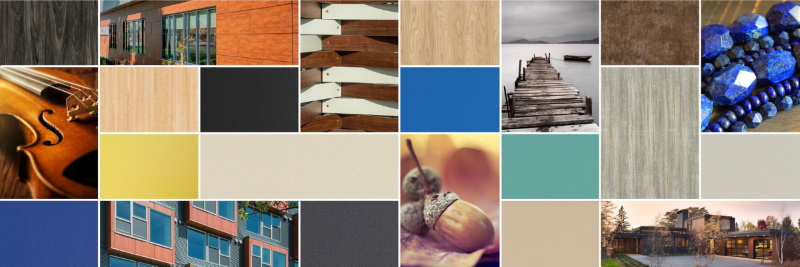

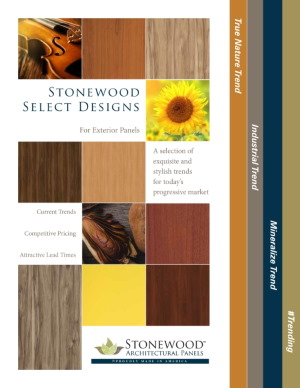

MEG Panel Offering: Italian Design, 92 Colors, Large Format Panels

|

|

|

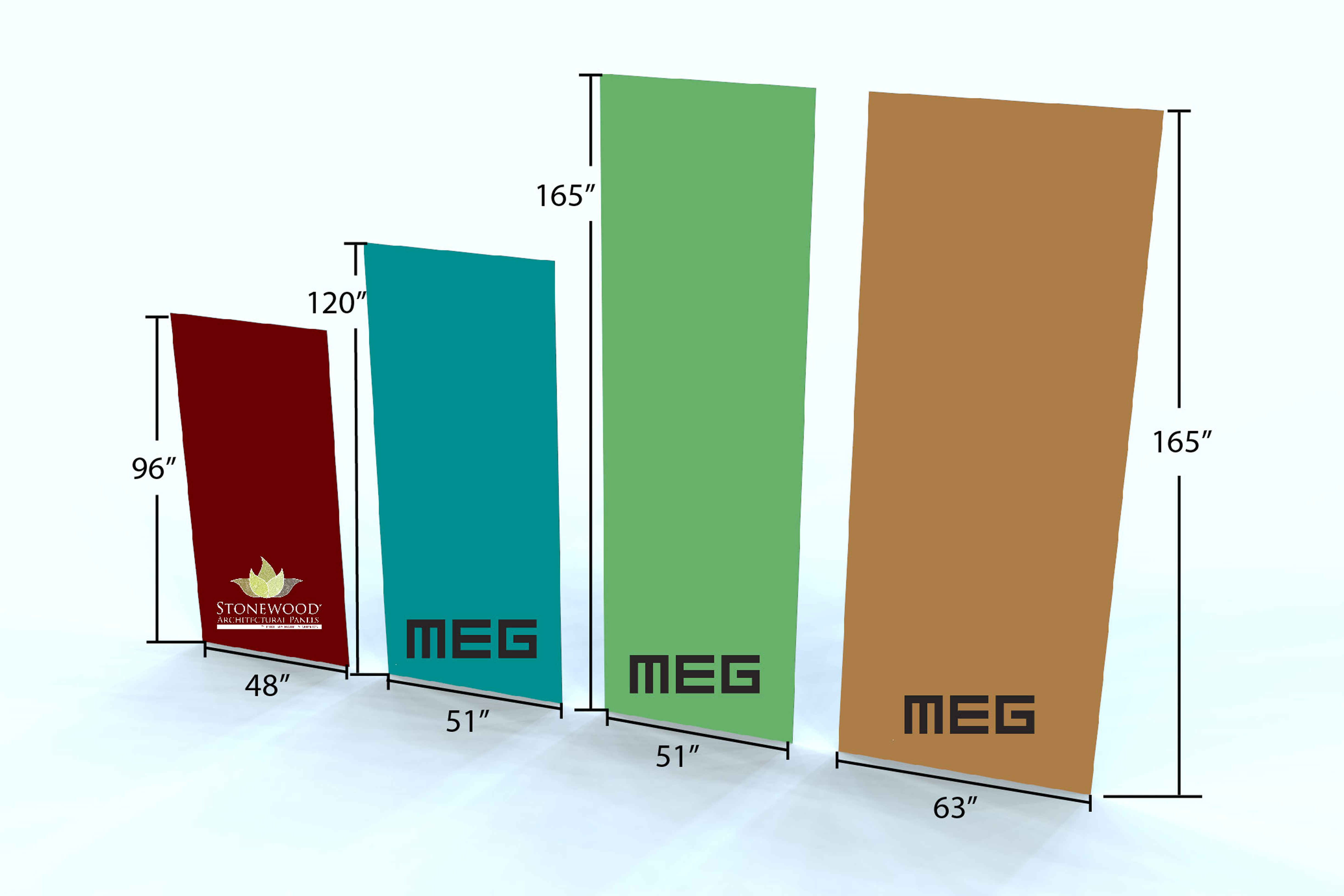

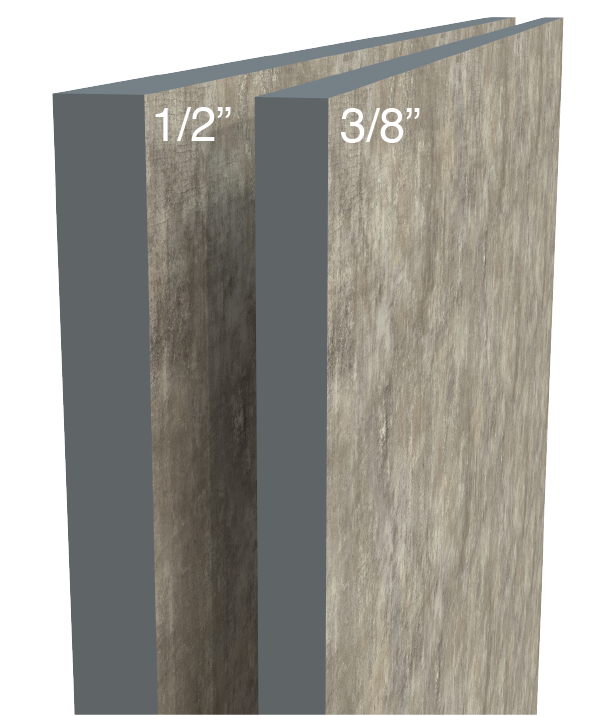

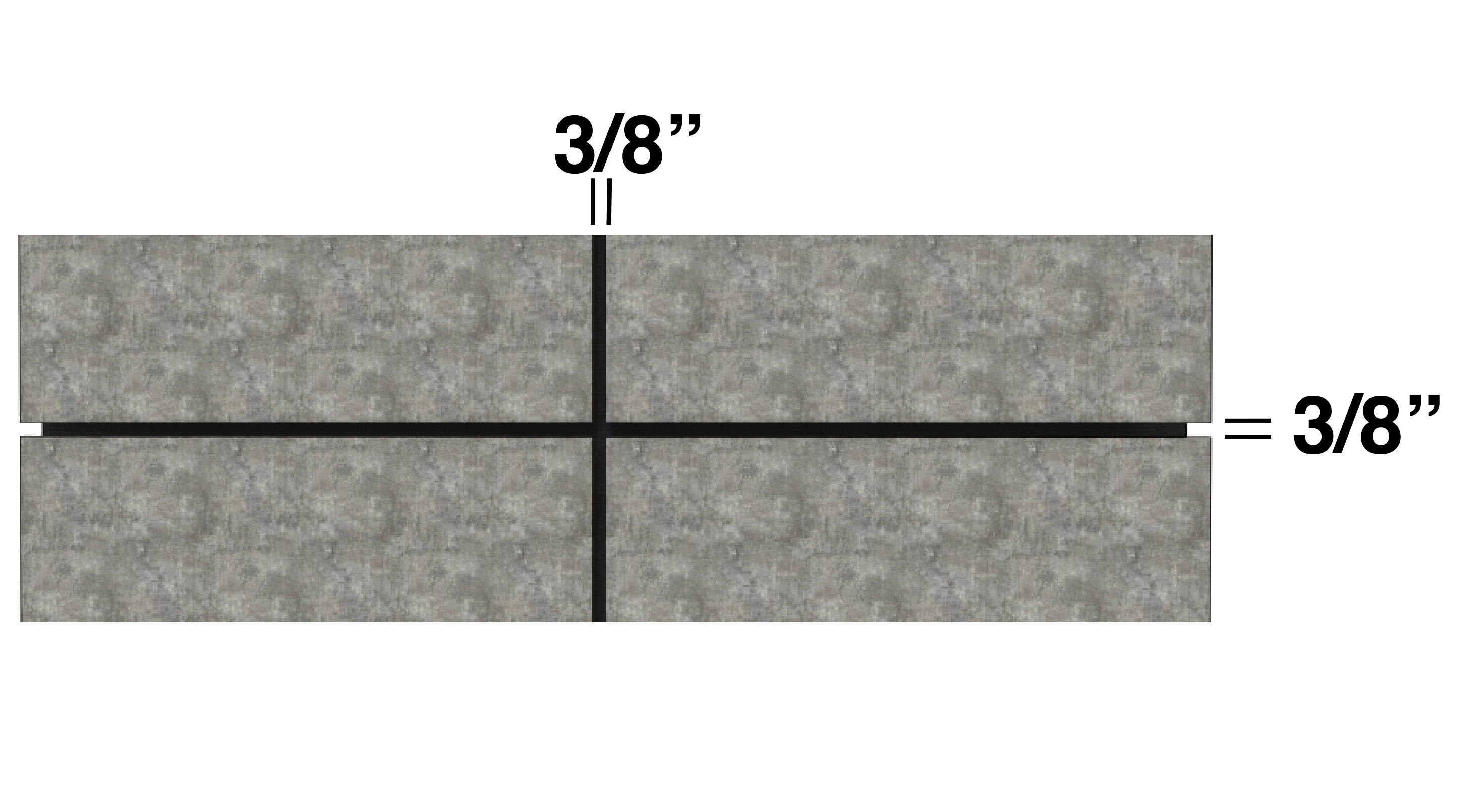

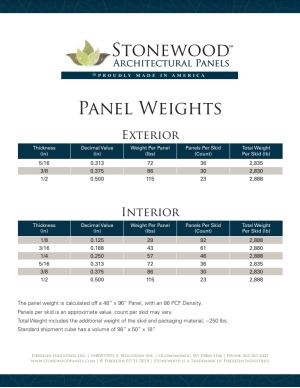

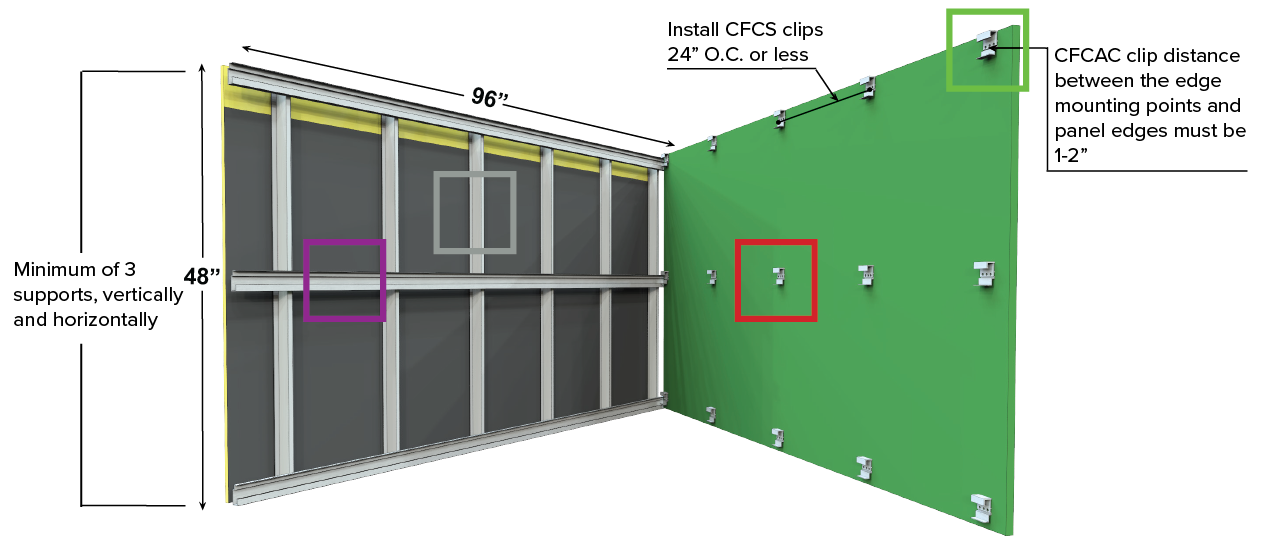

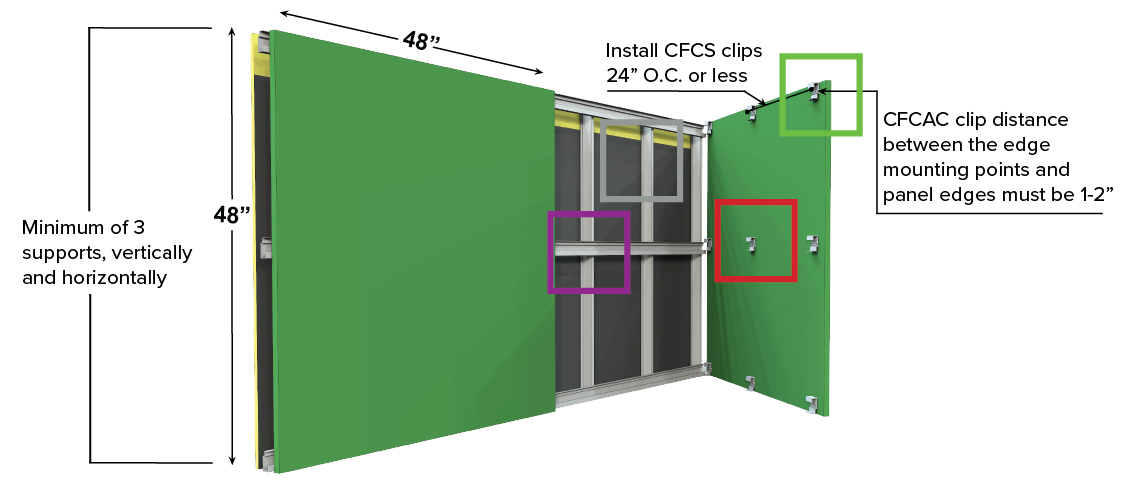

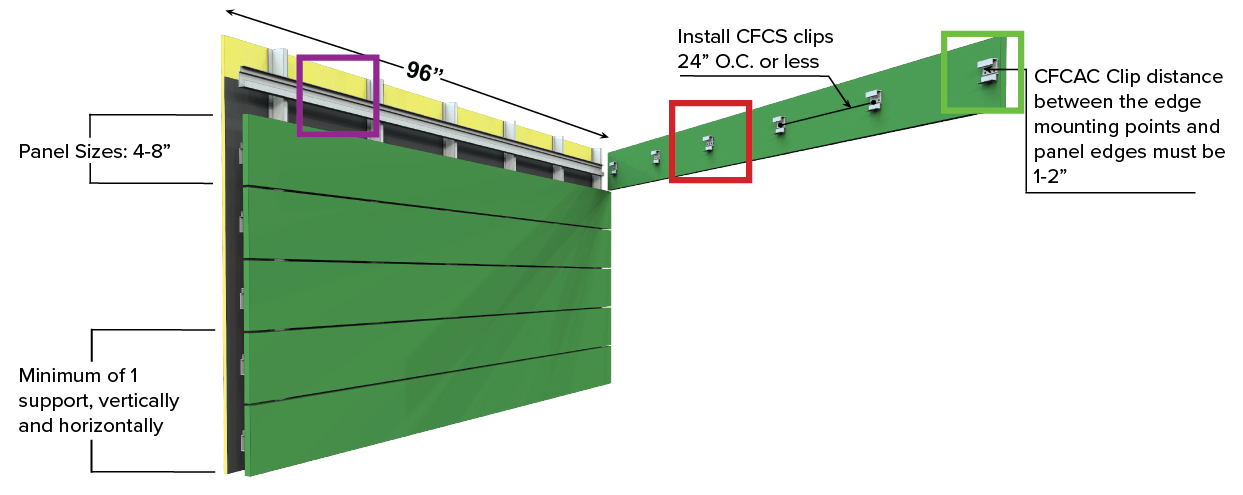

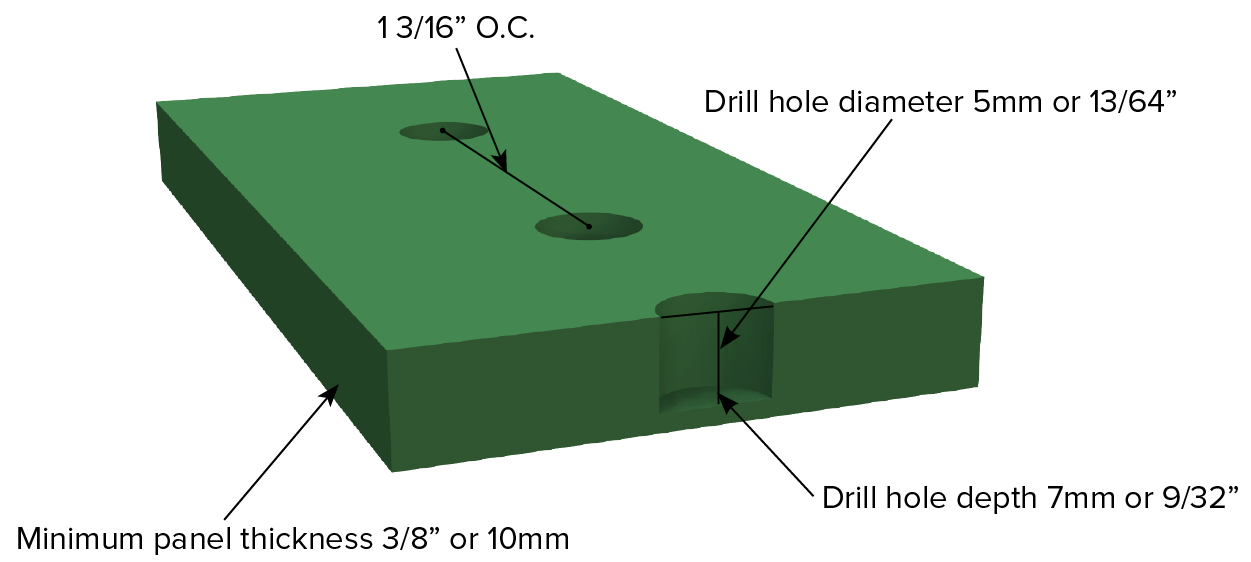

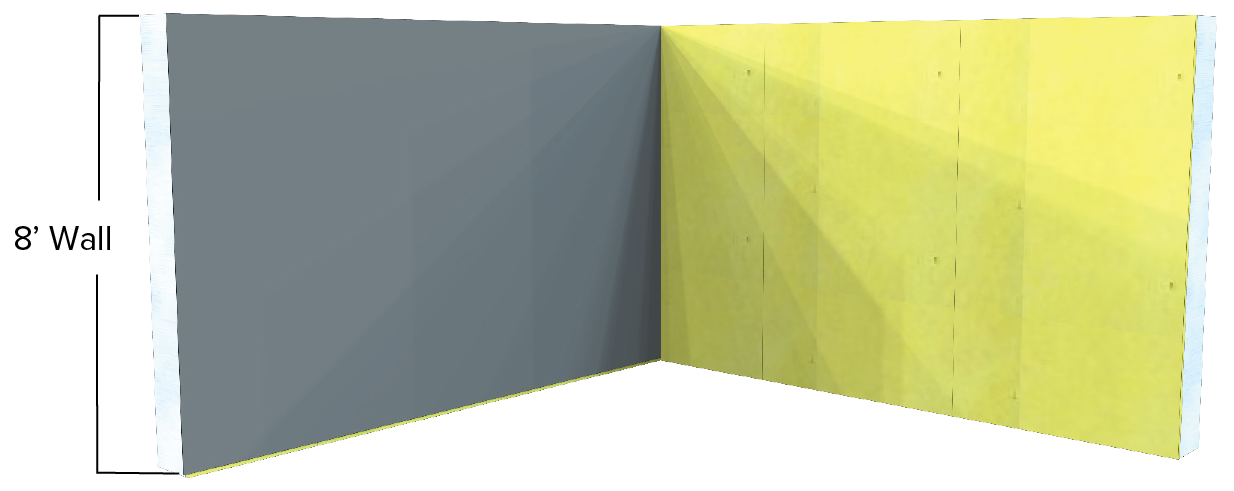

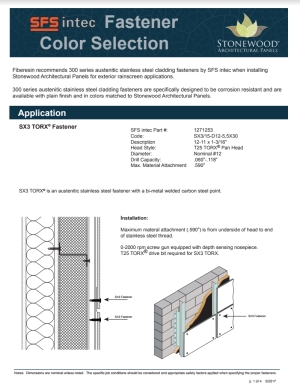

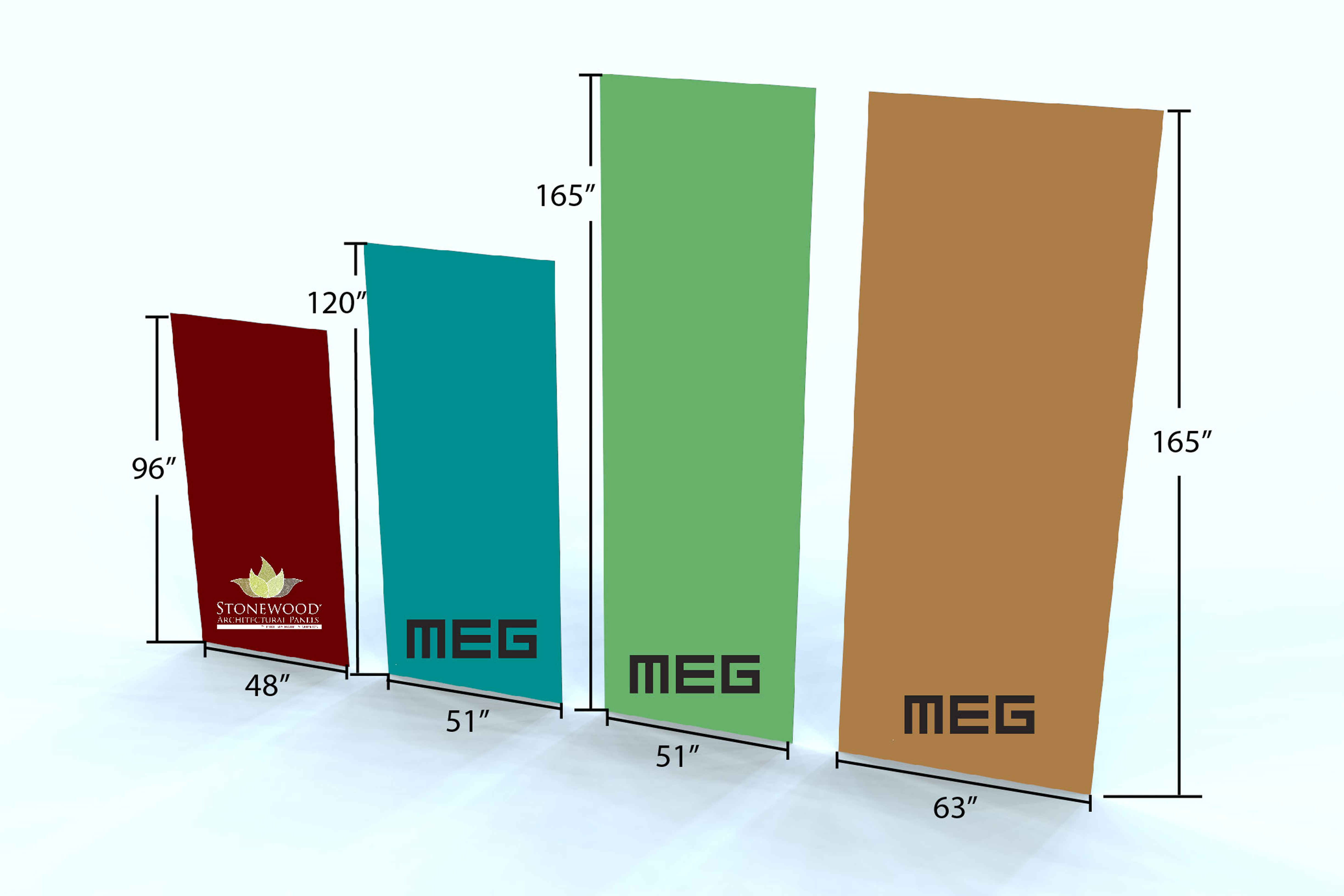

| Three large size panel formats are available. Panel thickness options are: 8mm, 10mm, 13mm. |

Expanded color palette, 92 Italian-inspired options are available. |

ABET Digital, large format printing, gives designers an endless array of design creativity. |

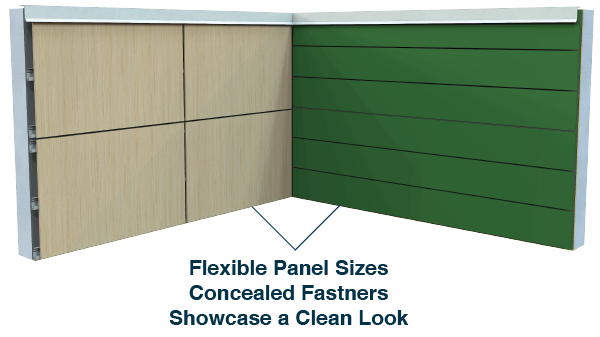

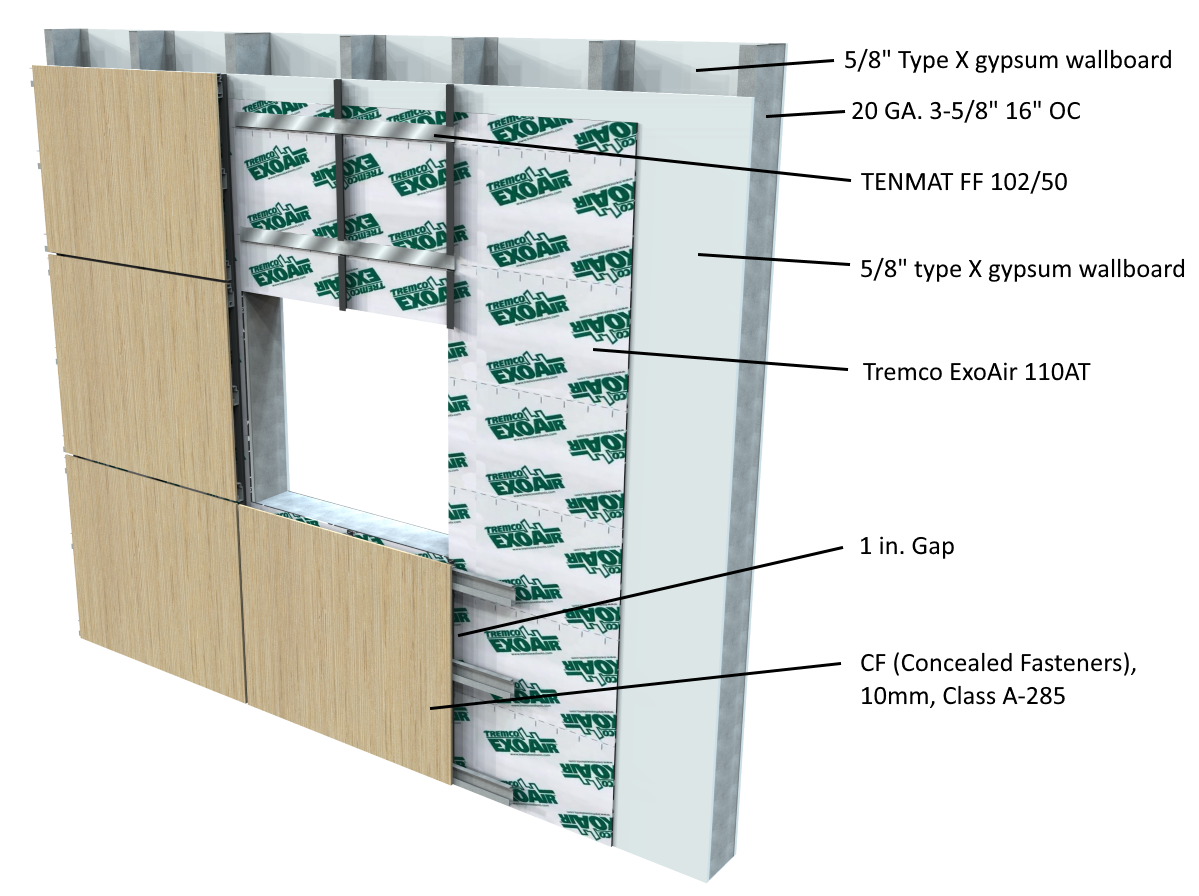

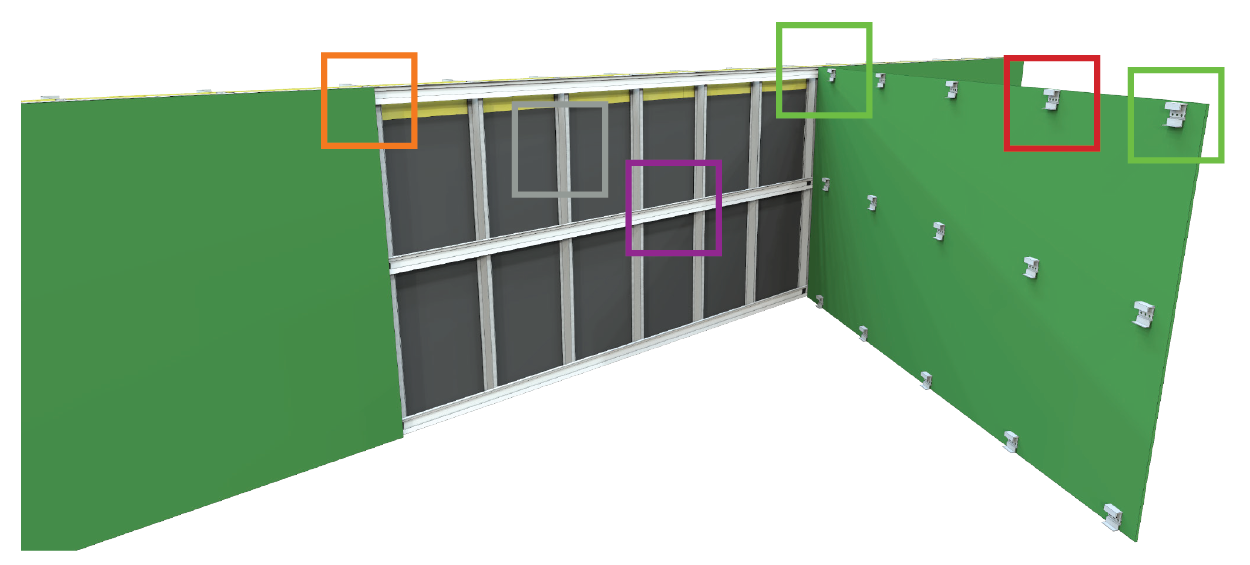

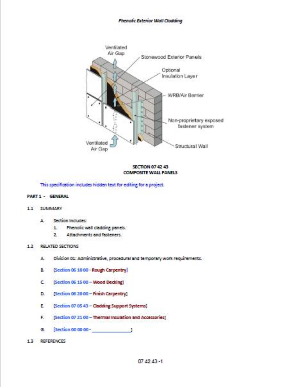

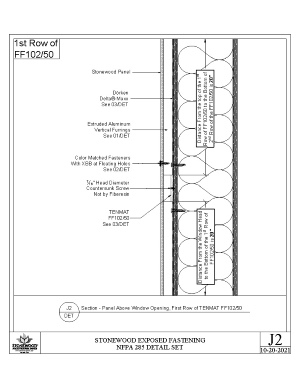

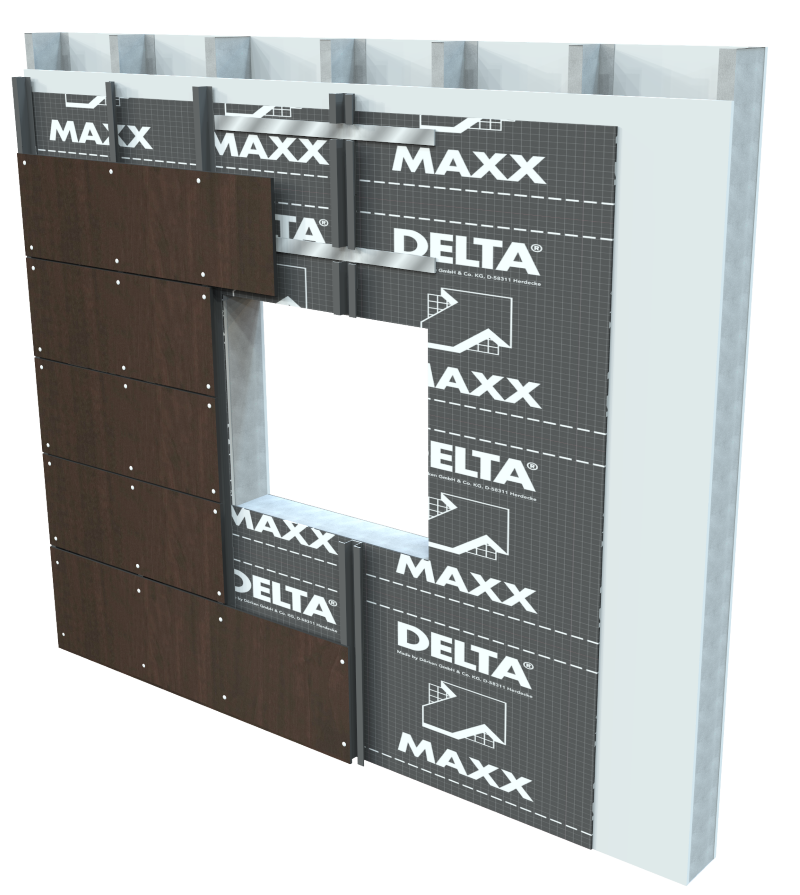

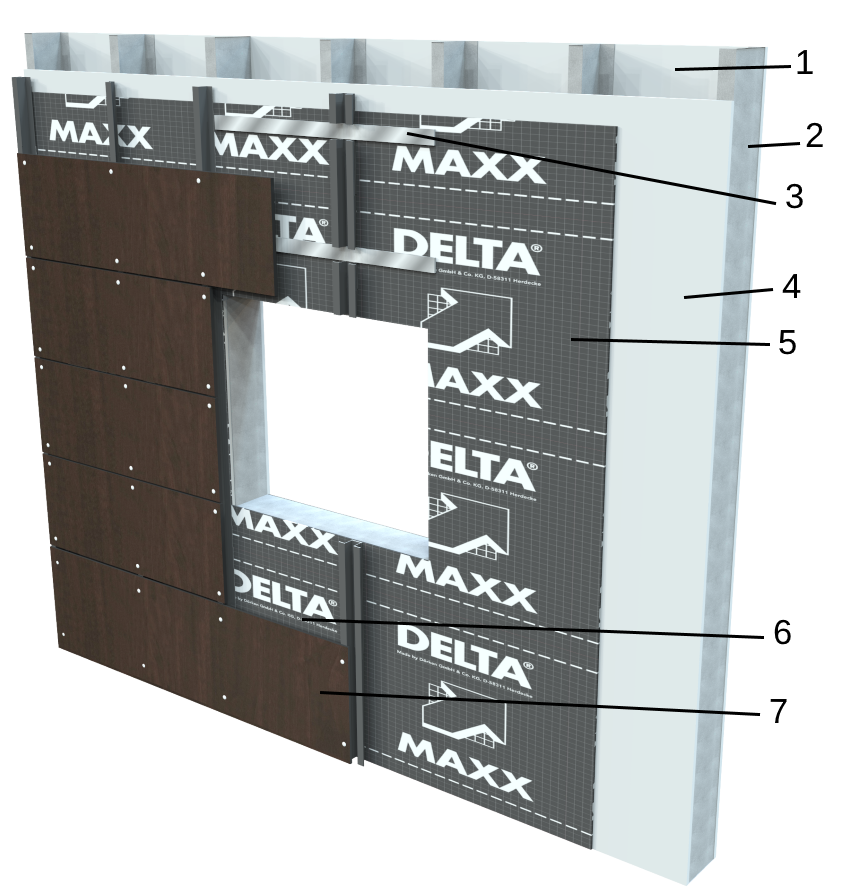

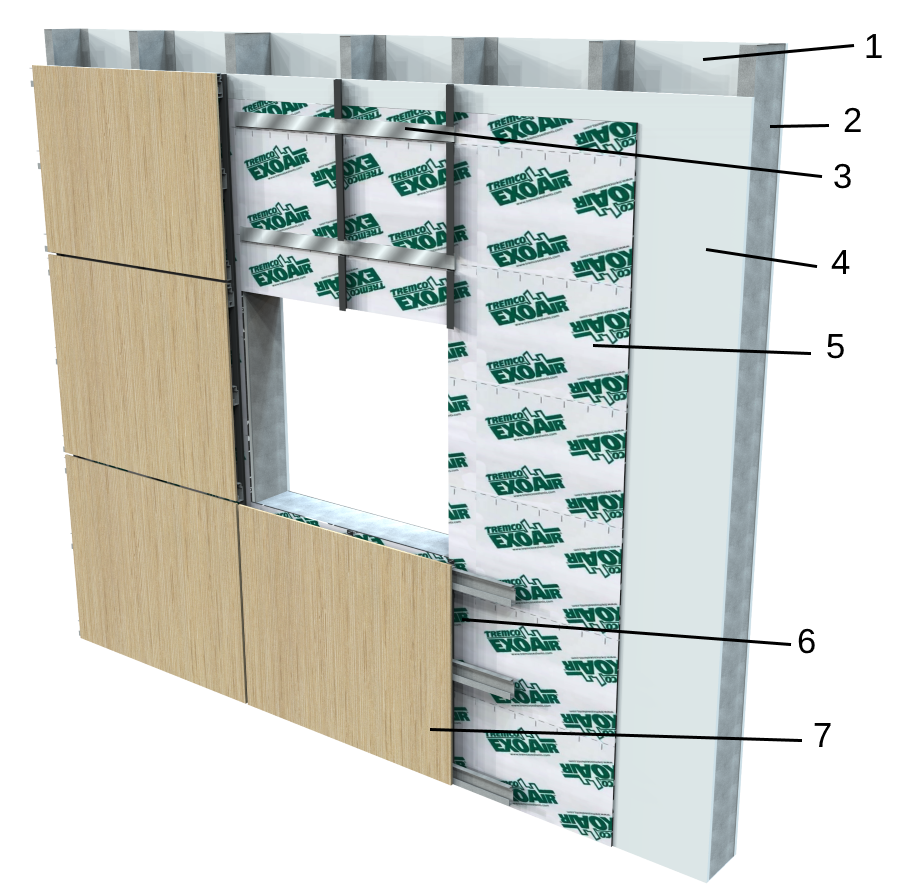

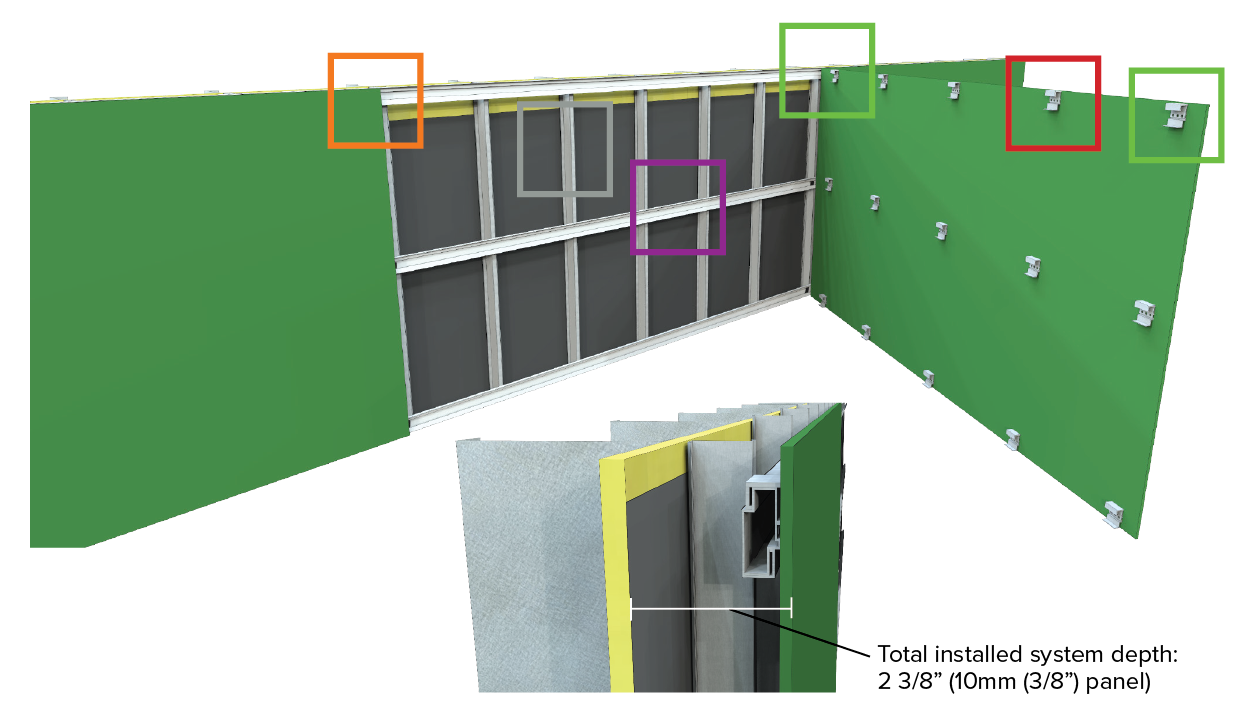

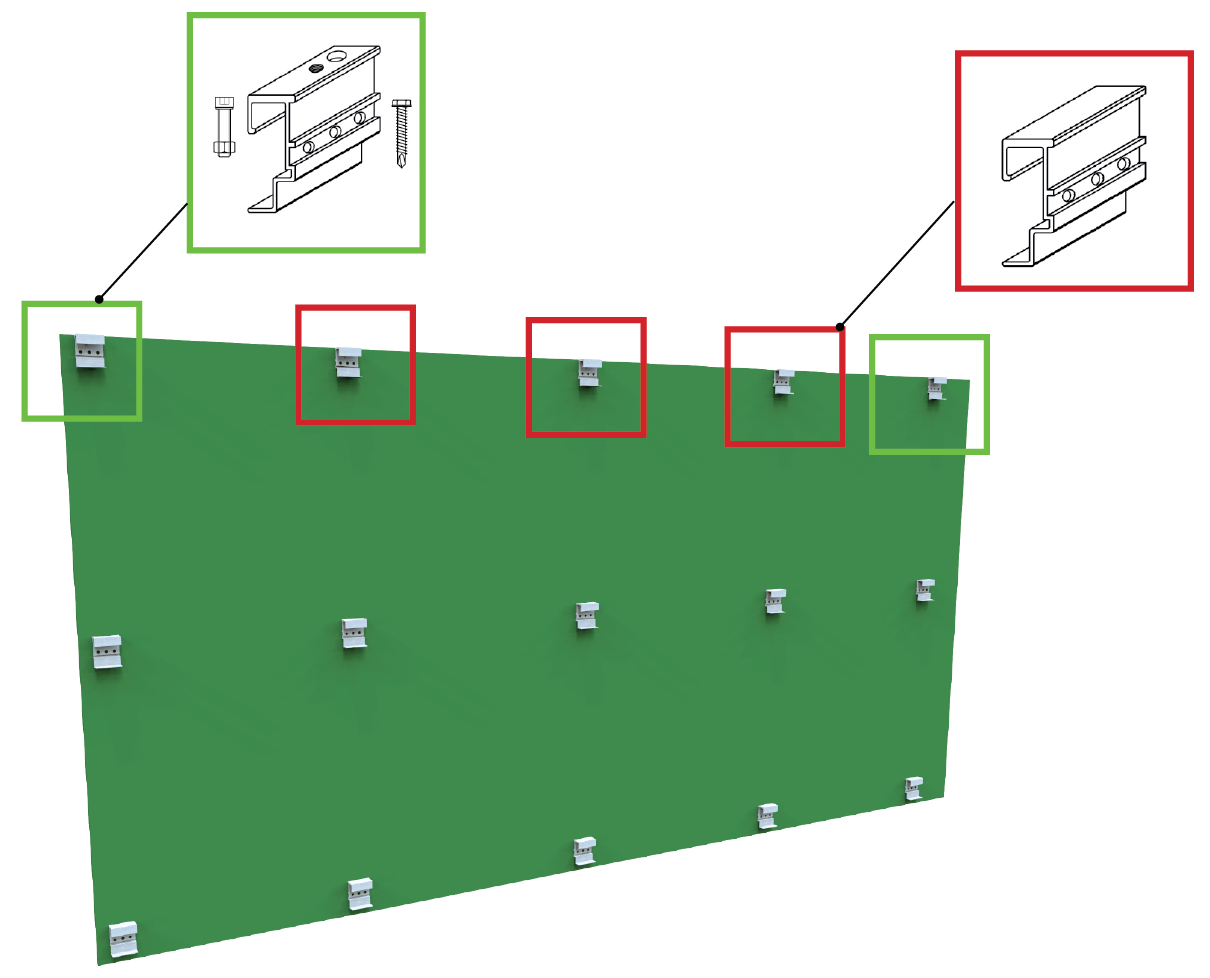

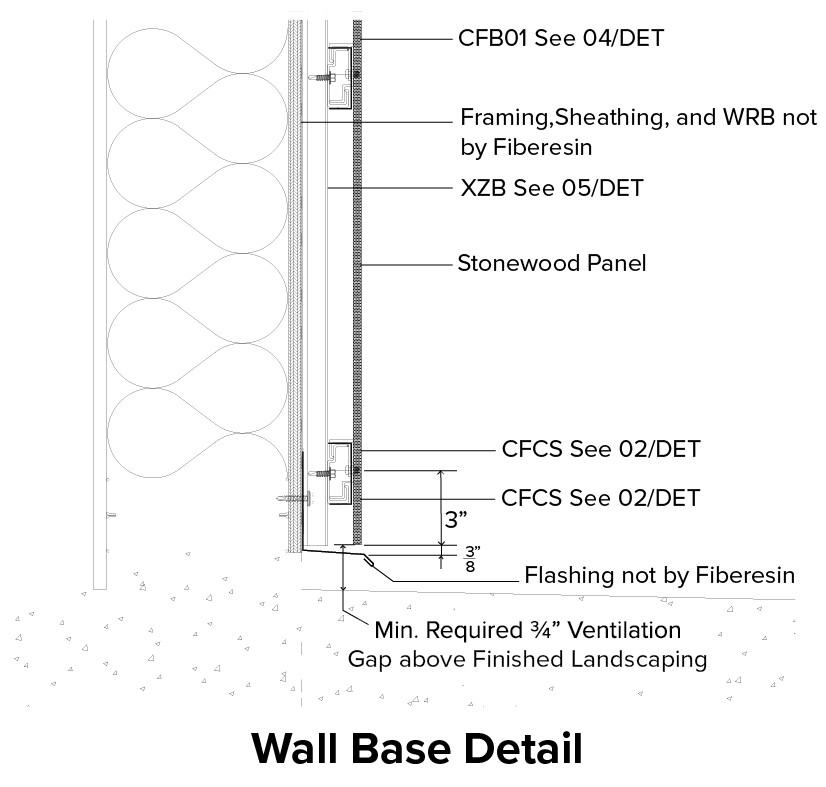

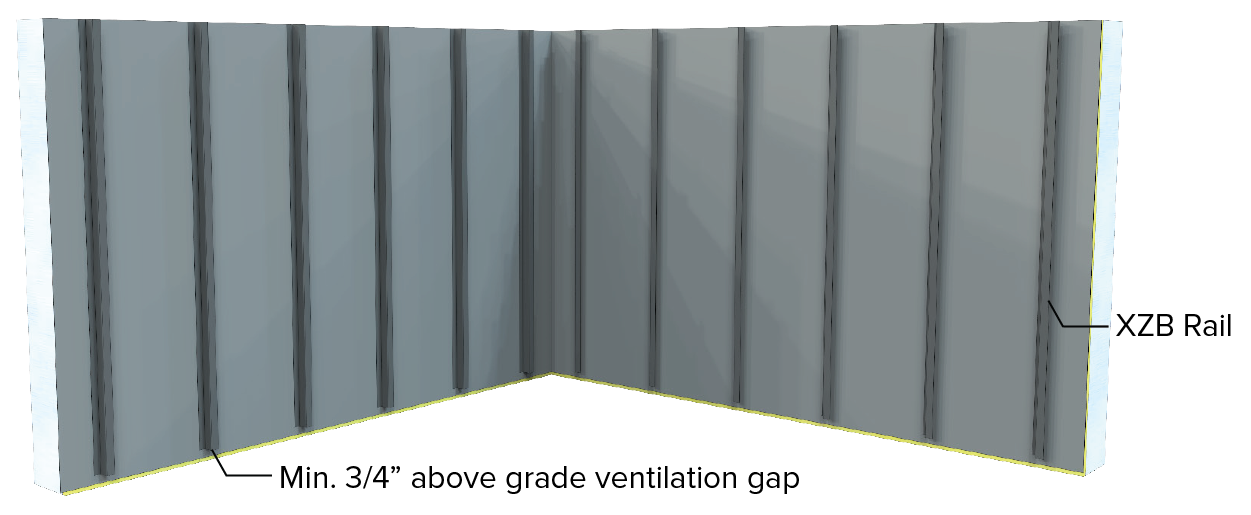

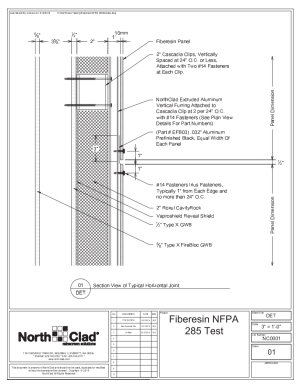

MEG exterior panels, selling worldwide since 1983, have a proven track recrod of success in the rainscreen facade market. Panels are secured using MEG exposed or concealed fastening systems and there is an additional exposed fastener option available for planks.

| Interested in Learning More? |

|

|

|

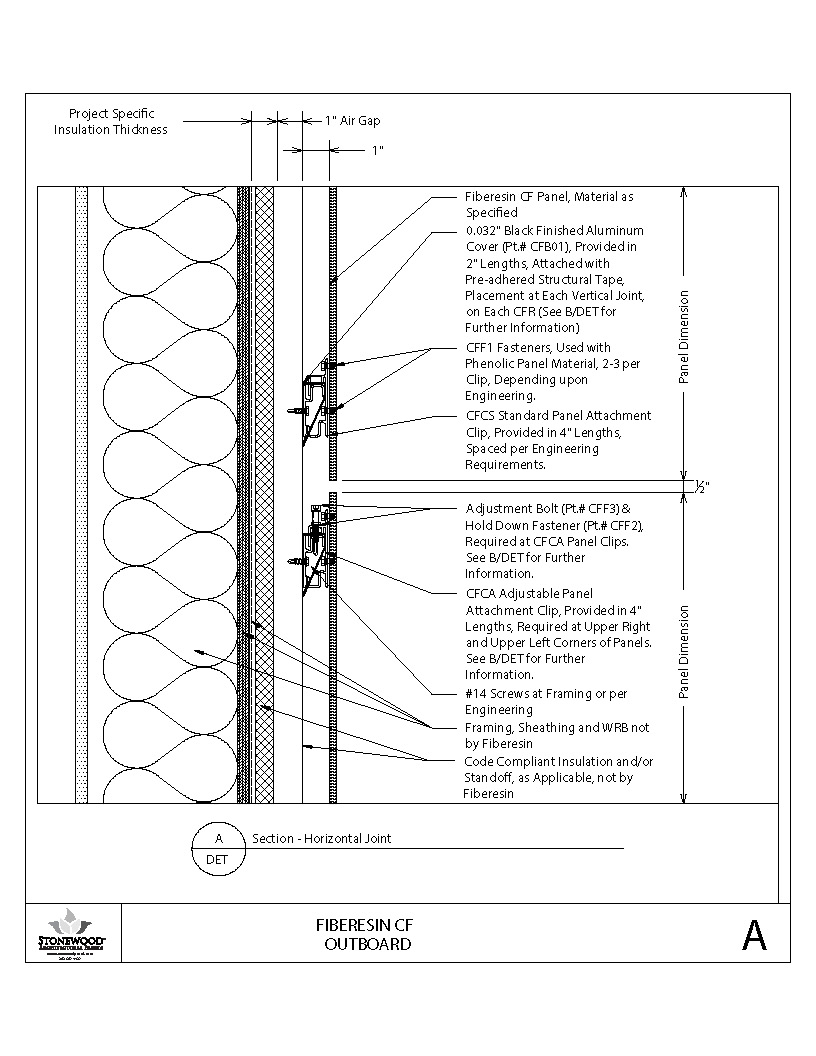

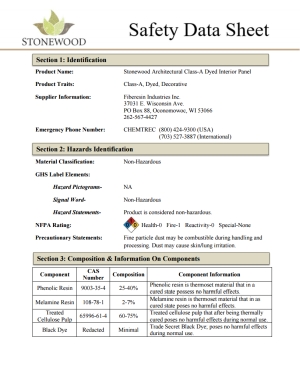

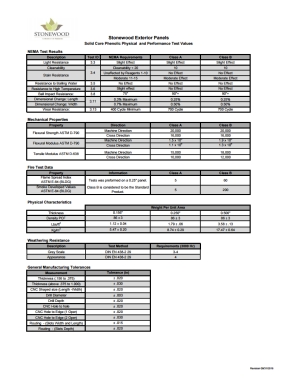

- Solid phenolic panels

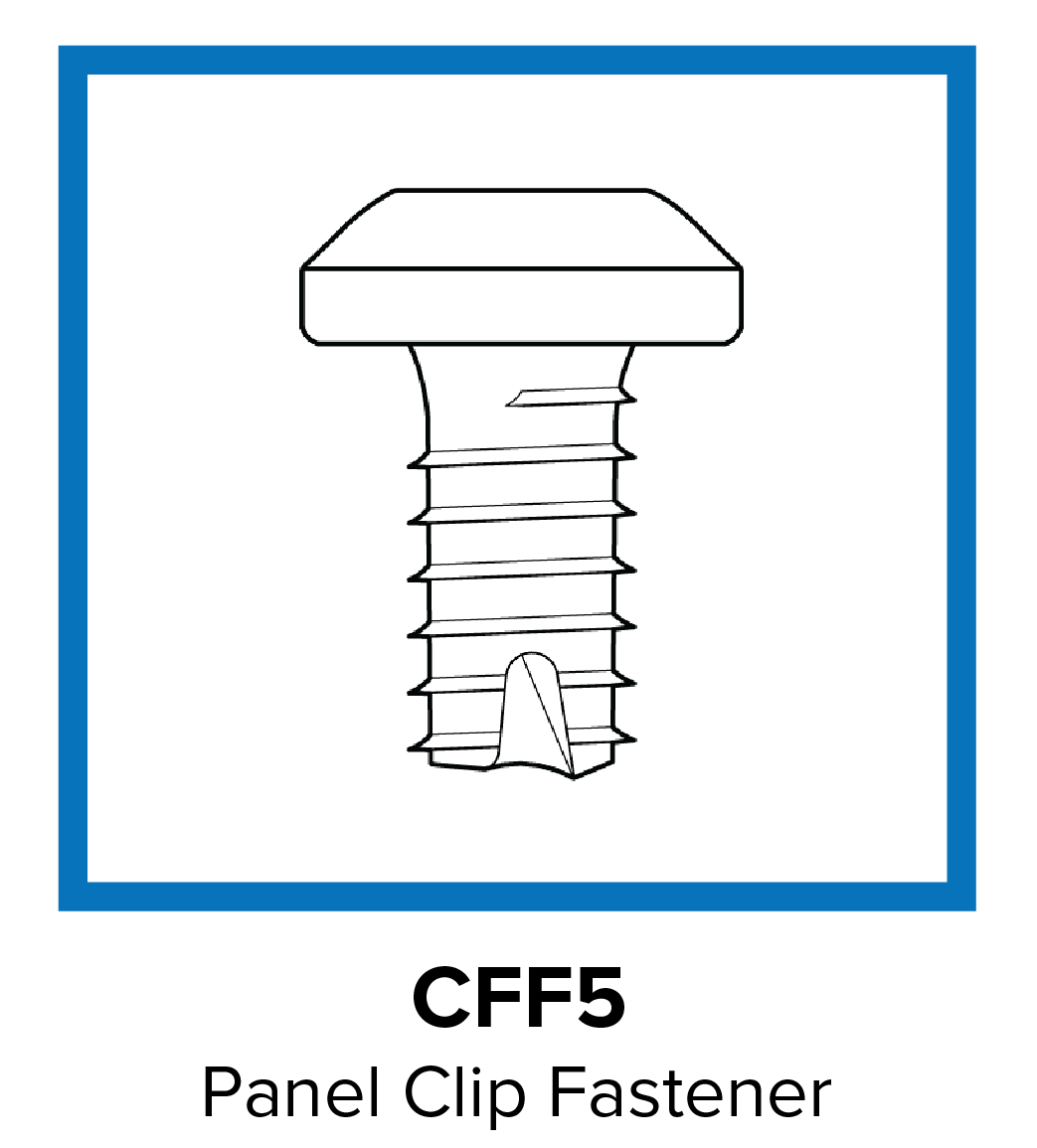

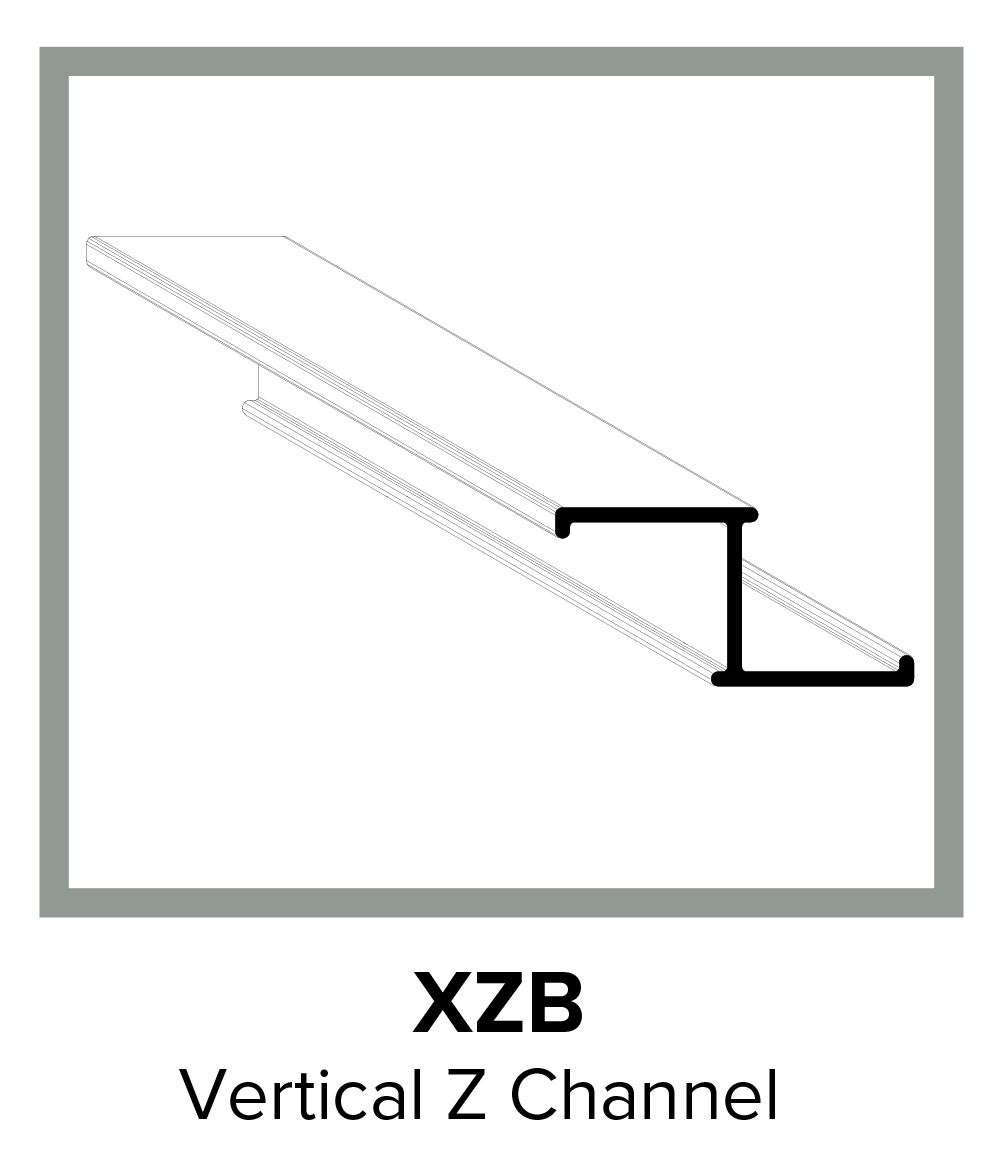

- Multiple fastening systems: Exposed or Concealed

- Panel sizes: 48" x 96", 7 5/8" x 96", 11 5/8" x 96", 15 3/4" x 96"

- Over 300 design offering choices

- Manufactured in Oconomowoc, WI

|

- Decorative laminate rainscreen facade panels

- Multiple fastening systems: Exposed or Concealed

- Large panel sizes: 120" x 51", 165" x 51", 63" x 165"

- 92 Italian-inspired designs

- Manufactured in Bra, Italy

|

- Kits include four 120" x 8" x 5/16" planks (3050mm x 208mm x 8mm) and attachment hardware

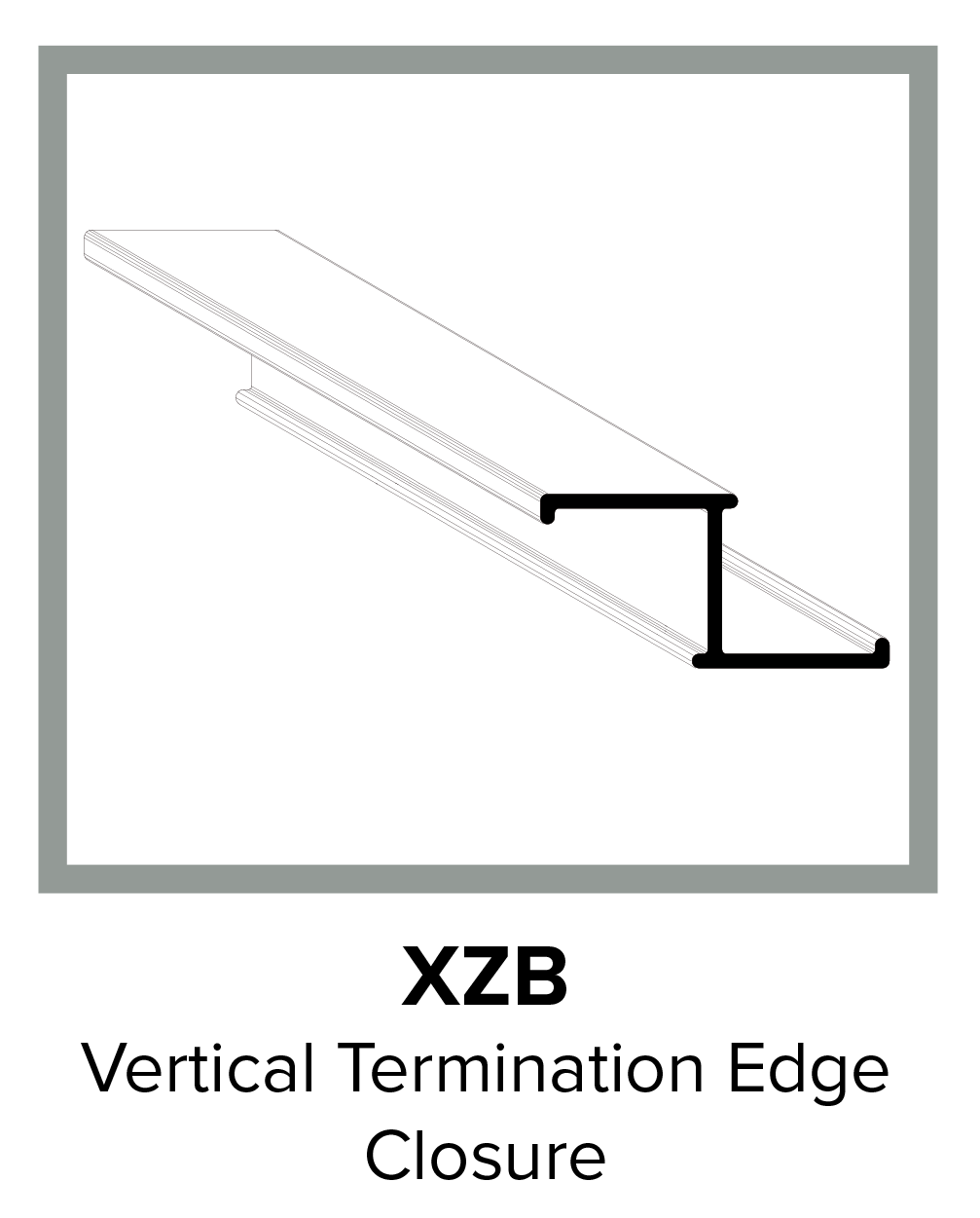

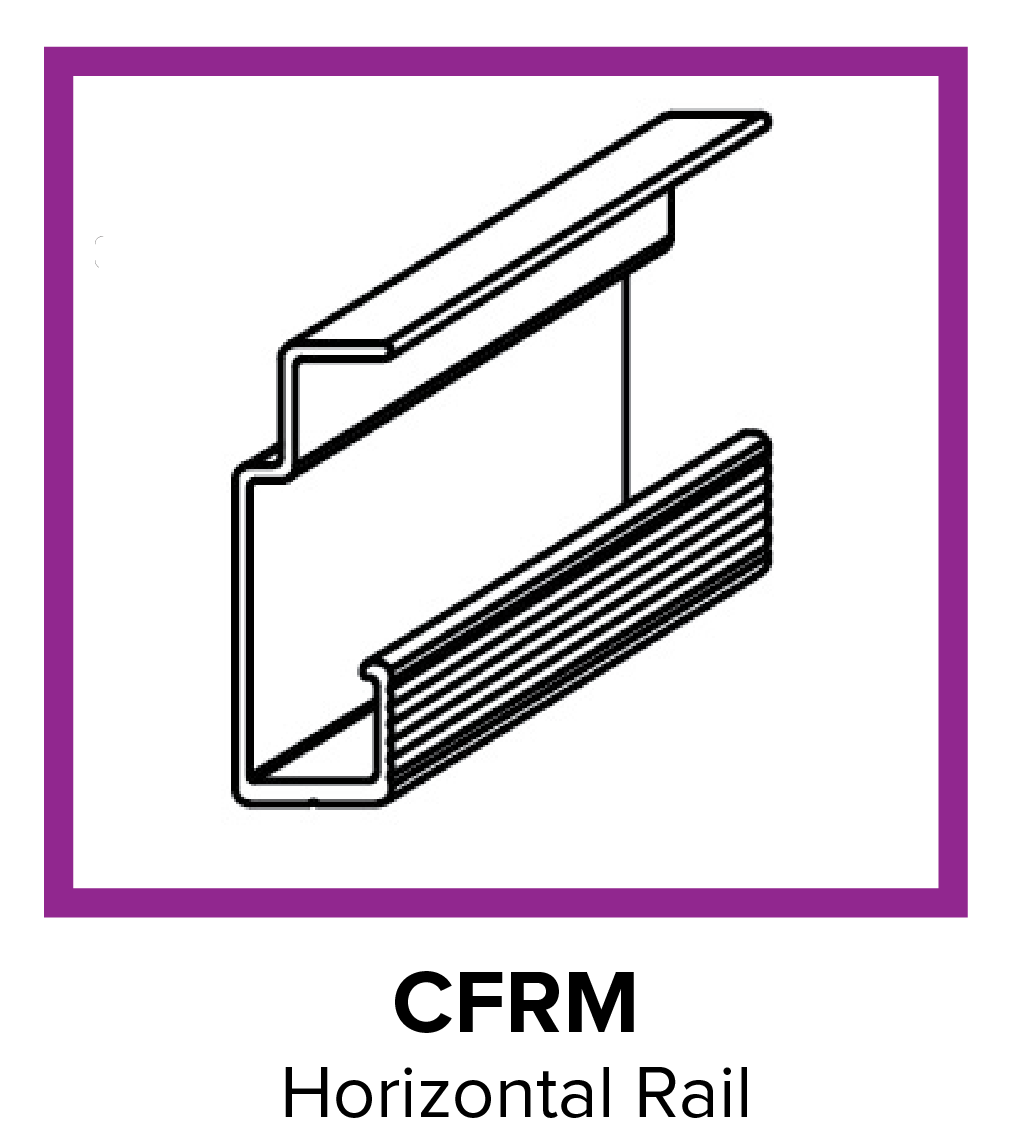

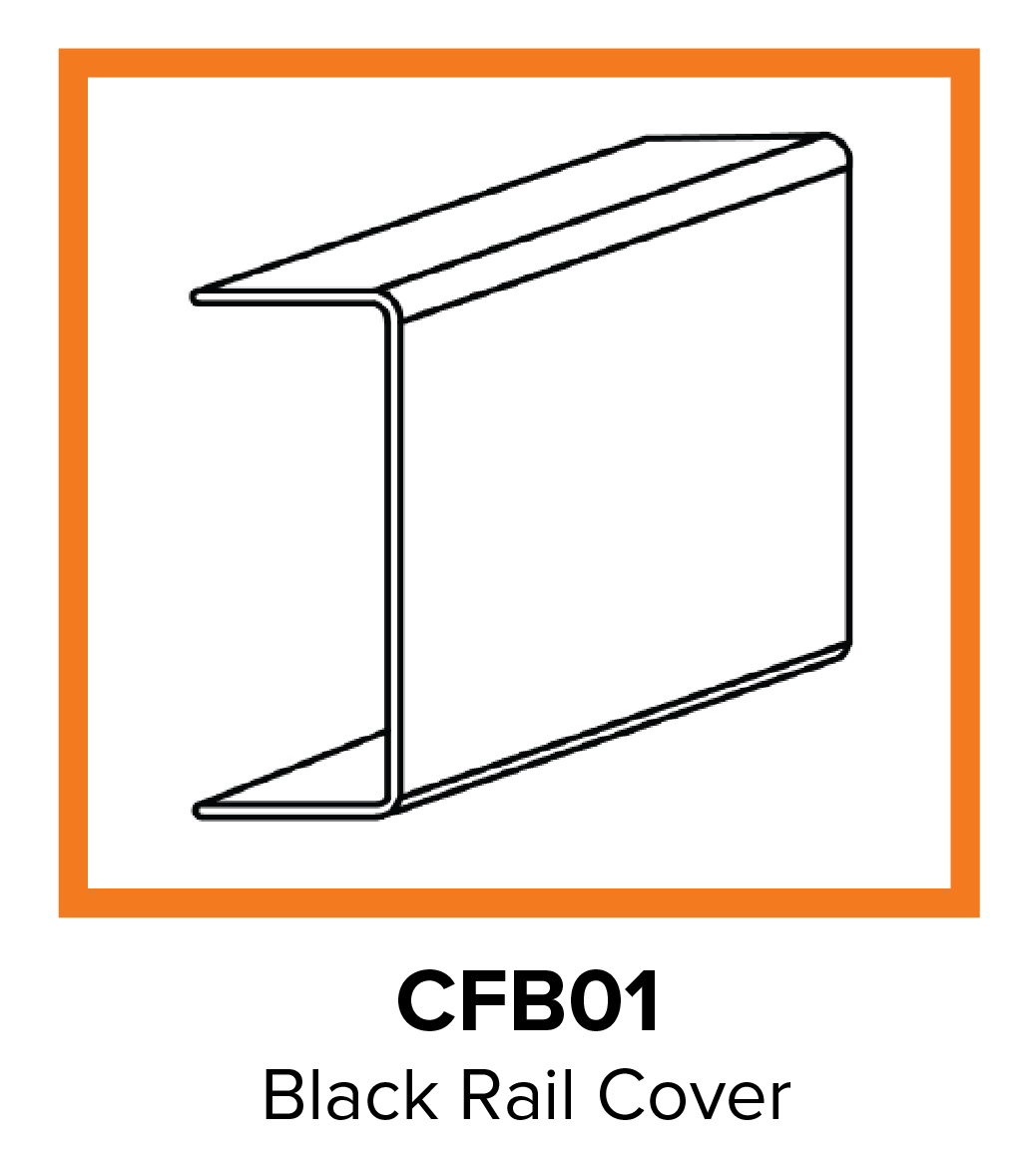

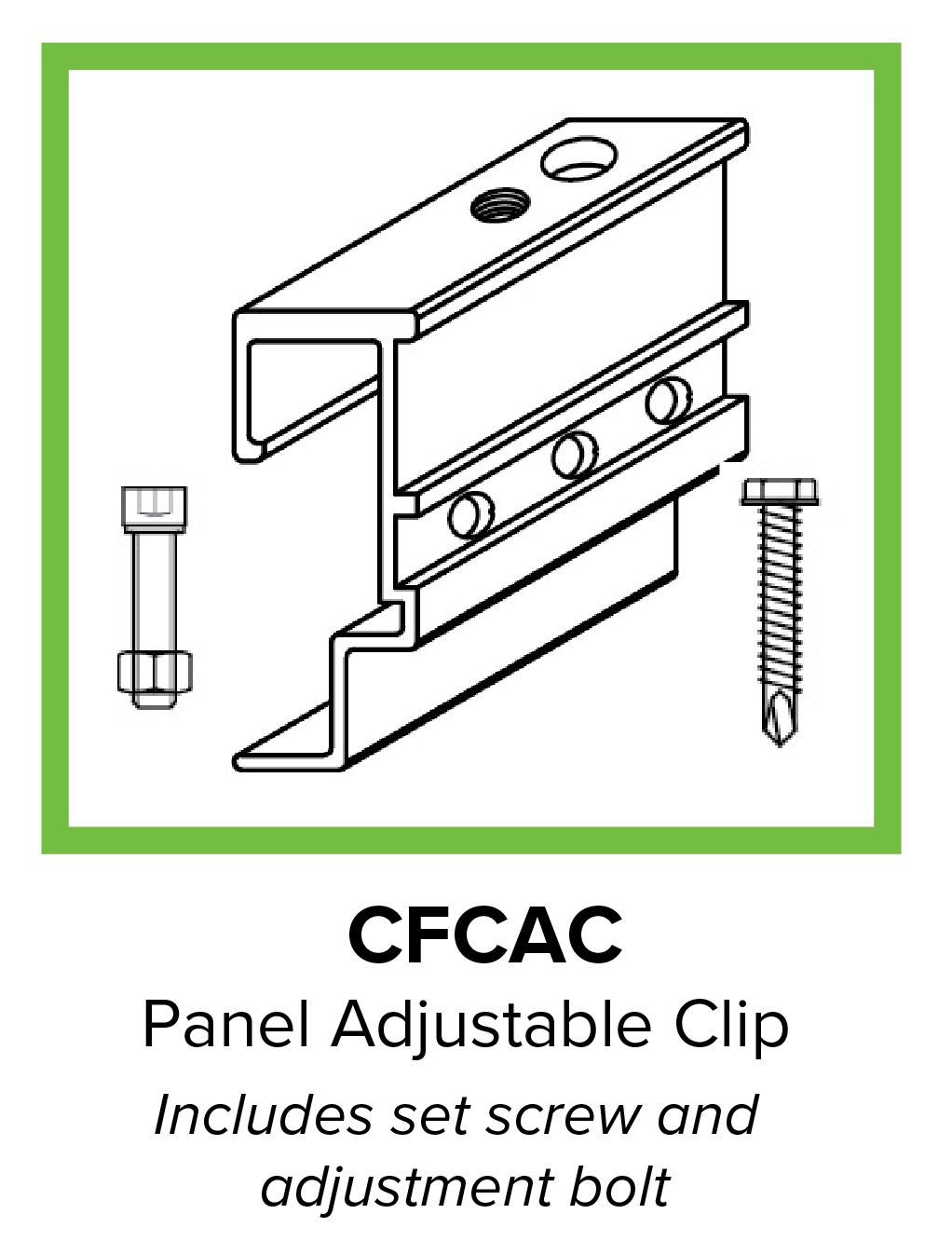

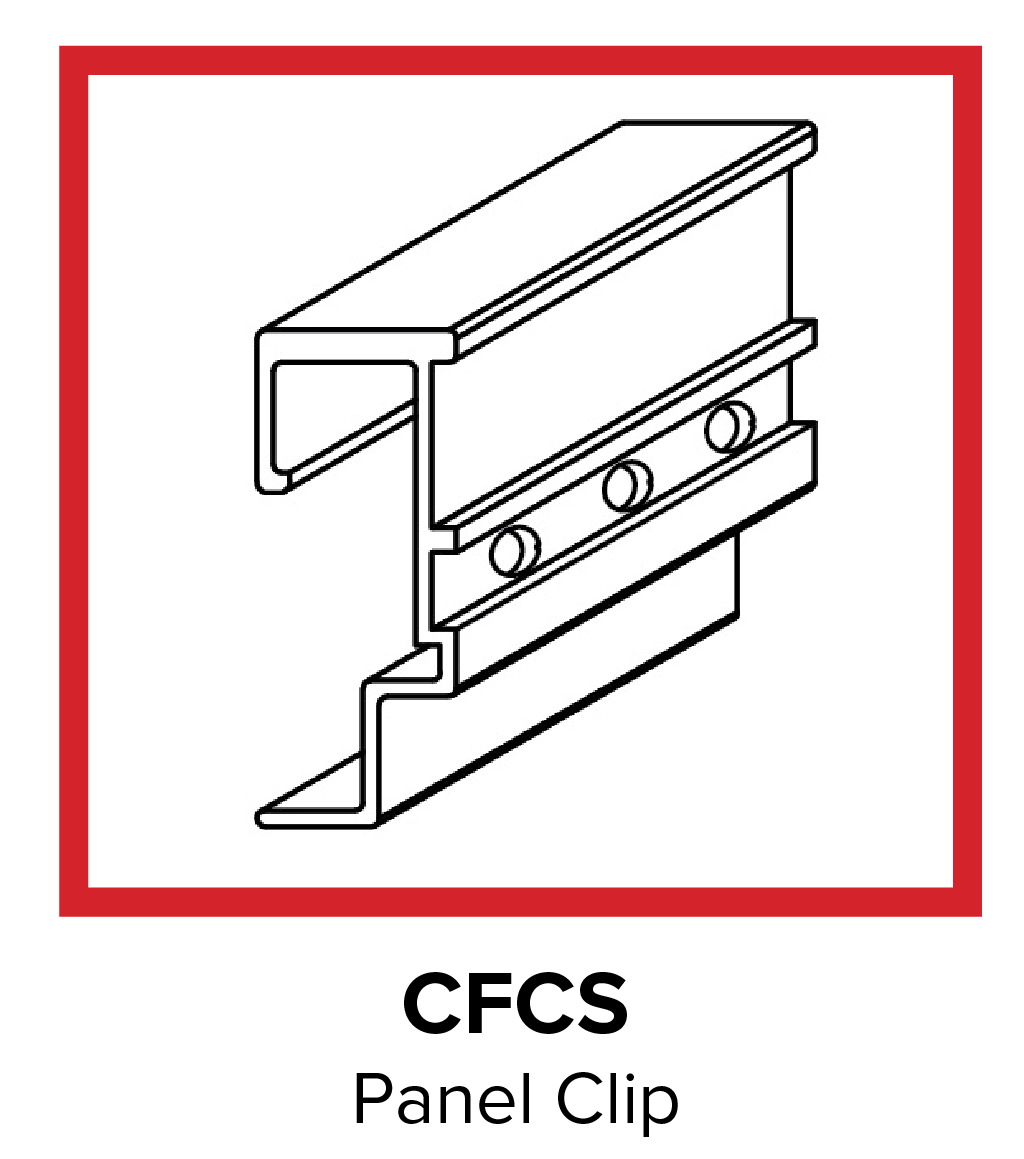

- Attachment hardware includes: Open Joint and Overlapping Clips

- 16 colors are available worldwide: 6 solid and 10 woodgrains

|

Fiberesin Industries is committed to protecting your privacy and developing technology that gives you the most powerful and safe online experience. This Statement of Privacy applies to websites owned by Fiberesin Industries including edgemold.com, stonewoodpanels.com, and fiberesin.com (Fiberesin Sites) and governs data collection and usage. By using a Fiberesin Site, you consent to the data practices described in this statement.

Collection of your Personal Information

Fiberesin Industries provides an opportunity for you to enter your contact information on the Fiberesin Sites so that we may communicate with you. If you provide this information, we store it for future use by our employees and consultants. This personally identifiable information includes your email address, name, home or work address or telephone number.

There is also information about your computer hardware and software that is automatically collected by Fiberesin Industries. This information can include: your IP address, browser type, domain names, access times and referring website addresses. This information is used by Fiberesin Industries for the operation of the service, to maintain quality of the service, and to provide general statistics regarding use of the Fiberesin Industries site.

Fiberesin Industries encourages you to review the privacy statements of Web sites you choose to link to from Fiberesin Industries so that you can understand how those Web sites collect, use and share your information. Fiberesin Industries is not responsible for the privacy statements or other content on Web sites outside of the Fiberesin Industries and Fiberesin Industries family of Web sites.

Use of your Personal Information

Fiberesin Industries collects and uses your personal information to operate the Fiberesin Industries Web site and deliver the services you have requested. Fiberesin Industries also uses your personally identifiable information to inform you of other products or services available from Fiberesin Industries. Fiberesin Industries may also contact you via surveys to conduct research about your opinion of current services or of potential new services that may be offered.

Fiberesin Industries does not sell, rent or lease its customer lists to third parties. Fiberesin Industries may, from time to time, contact you on behalf of external business partners about a particular offering that may be of interest to you. In those cases, your unique personally identifiable information (e-mail, name, address, telephone number) is not transferred to the third party. In addition, Fiberesin Industries may share data with trusted partners to help us perform statistical analysis, send you email or postal mail, provide customer support, or arrange for deliveries. All such third parties are prohibited from using your personal information except to provide these services to Fiberesin Industries, and they are required to maintain the confidentiality of your information.

Fiberesin Industries does not use or disclose sensitive personal information, such as race, religion, or political affiliations, without your explicit consent.

Fiberesin Industries keeps track of the Web sites and pages our customers visit within Fiberesin Industries, in order to determine what Fiberesin Industries services are the most popular. This data is used to deliver customized content and advertising within Fiberesin Industries to customers whose behavior indicates that they are interested in a particular subject area.

Fiberesin Industries Web sites will disclose your personal information, without notice, only if required to do so by law or in the good faith belief that such action is necessary to: (a) conform to the edicts of the law or comply with legal process served on Fiberesin Industries or the site; (b) protect and defend the rights or property of Fiberesin Industries; and, (c) act under exigent circumstances to protect the personal safety of users of Fiberesin Industries, or the public.

Use of Cookies

The Fiberesin Industries Web site use "cookies" to help you personalize your online experience. A cookie is a text file that is placed on your hard disk by a Web page server. Cookies cannot be used to run programs or deliver viruses to your computer. Cookies are uniquely assigned to you, and can only be read by a web server in the domain that issued the cookie to you.

One of the primary purposes of cookies is to provide a convenience feature to save you time. The purpose of a cookie is to tell the Web server that you have returned to a specific page. For example, if you personalize Fiberesin Industries pages, or register with Fiberesin Industries site or services, a cookie helps Fiberesin Industries to recall your specific information on subsequent visits. This simplifies the process of recording your personal information, such as billing addresses, shipping addresses, and so on. When you return to the same Fiberesin Industries Web site, the information you previously provided can be retrieved, so you can easily use the Fiberesin Industries features that you customized.

You have the ability to accept or decline cookies. Most Web browsers automatically accept cookies, but you can usually modify your browser setting to decline cookies if you prefer. If you choose to decline cookies, you may not be able to fully experience the interactive features of the Fiberesin Industries services or Web sites you visit.

Security of your Personal Information

Fiberesin Industries secures your personal information from unauthorized access, use or disclosure. Fiberesin Industries secures the personally identifiable information you provide on computer servers in a controlled, secure environment, protected from unauthorized access, use or disclosure.

Changes to this Statement

Fiberesin Industries will occasionally update this Statement of Privacy to reflect company and customer feedback. Fiberesin Industries encourages you to periodically review this Statement to be informed of how Fiberesin Industries is protecting your information.

Contact Information

Fiberesin Industries welcomes your comments regarding this Statement of Privacy. If you believe that Fiberesin Industries has not adhered to this Statement, please contact Fiberesin Industries at gary.macdougal@taurlin.com. We will use commercially reasonable efforts to promptly determine and remedy the problem.