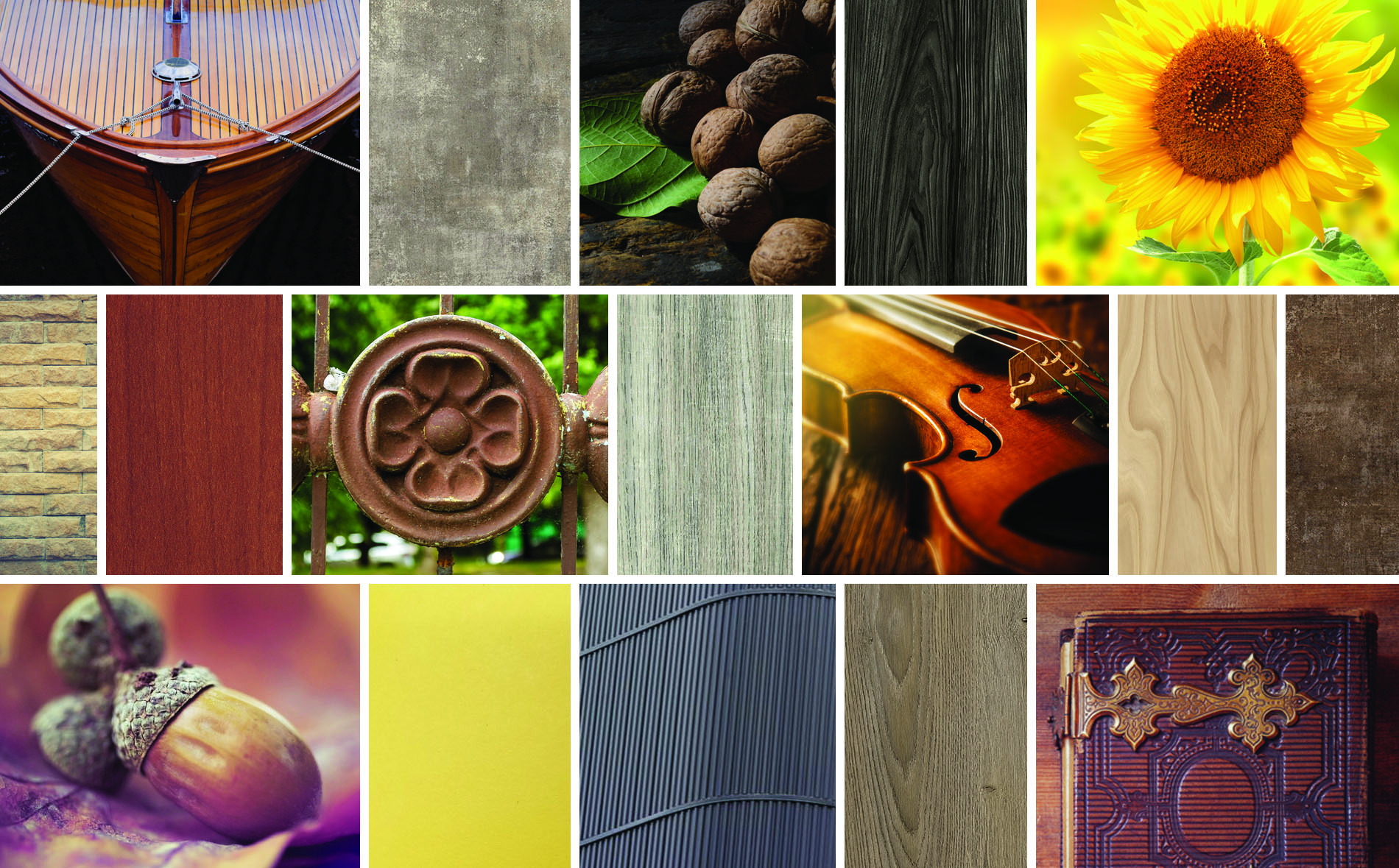

Stonewood Select | Mineralized Trend

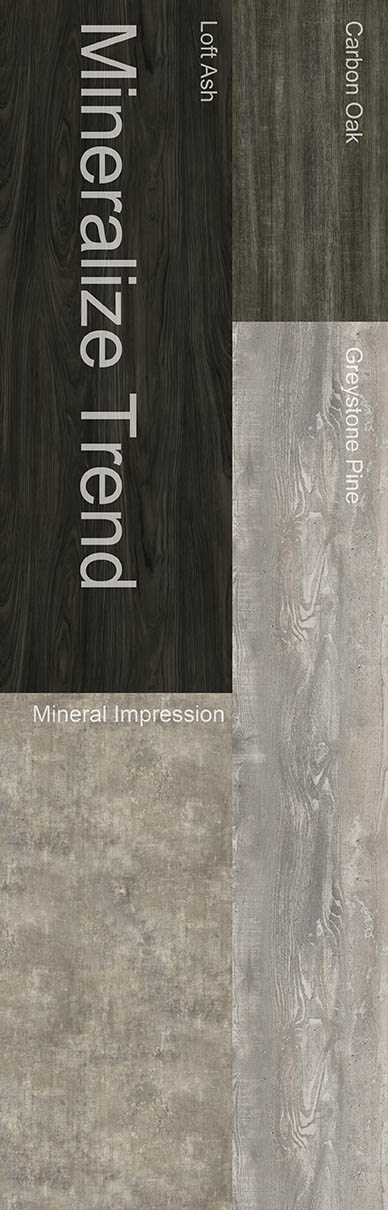

Mineralize is a trend based on the neutral grays that are seen in concrete, stone, and weathered woodgrains. It is commonly found with a perfect blend of warm and cool hues.

Mineralize is a trend based on the neutral grays that are seen in concrete, stone, and weathered woodgrains. It is commonly found with a perfect blend of warm and cool hues.

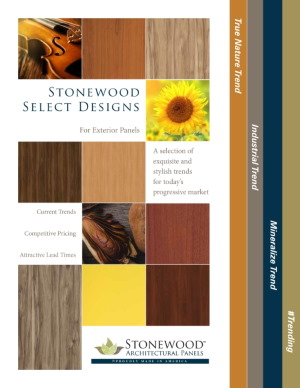

STONEWOOD SELECT DESIGNS

CURRENT TRENDS, COMPETITIVE PRICING, ATTRACTIVE LEAD TIMES

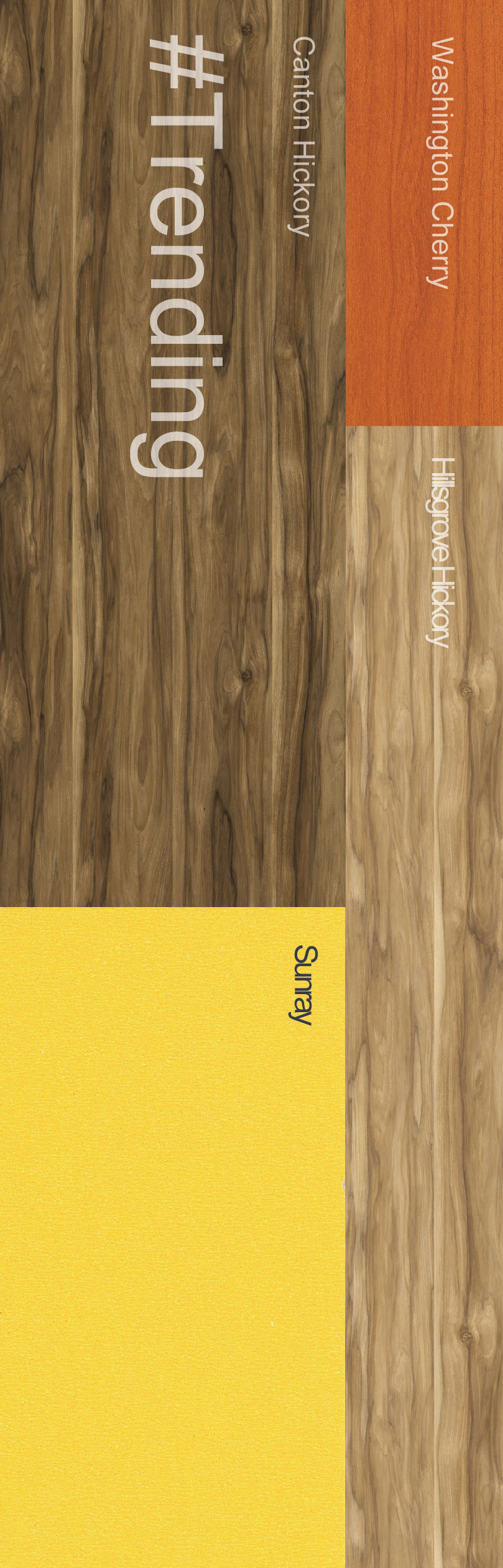

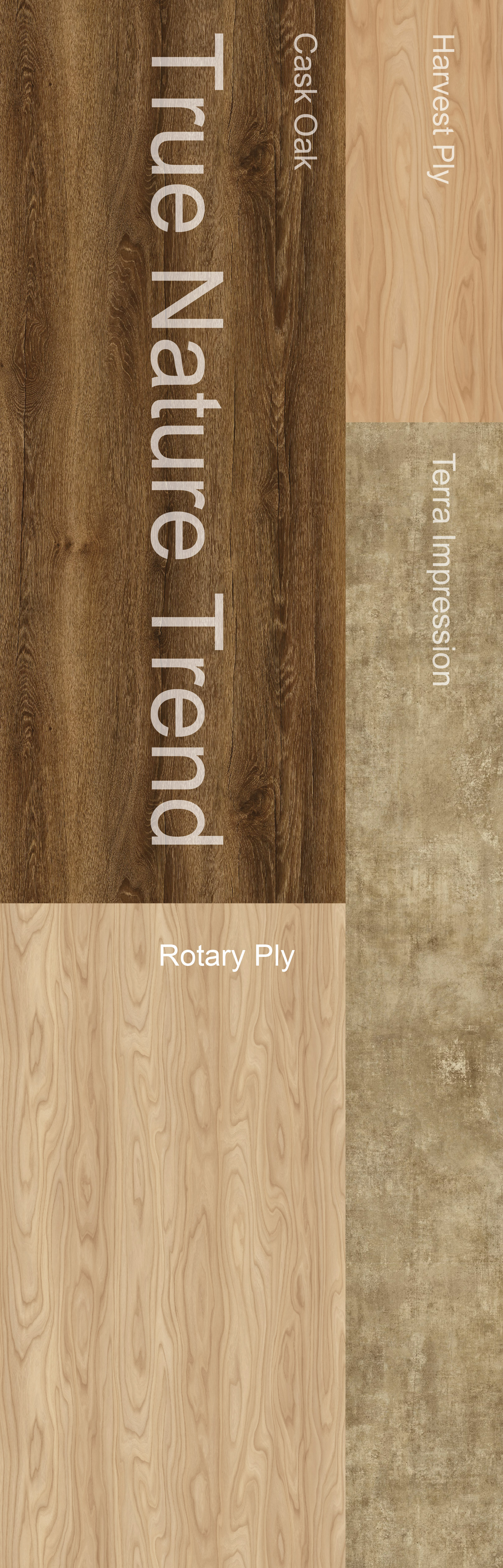

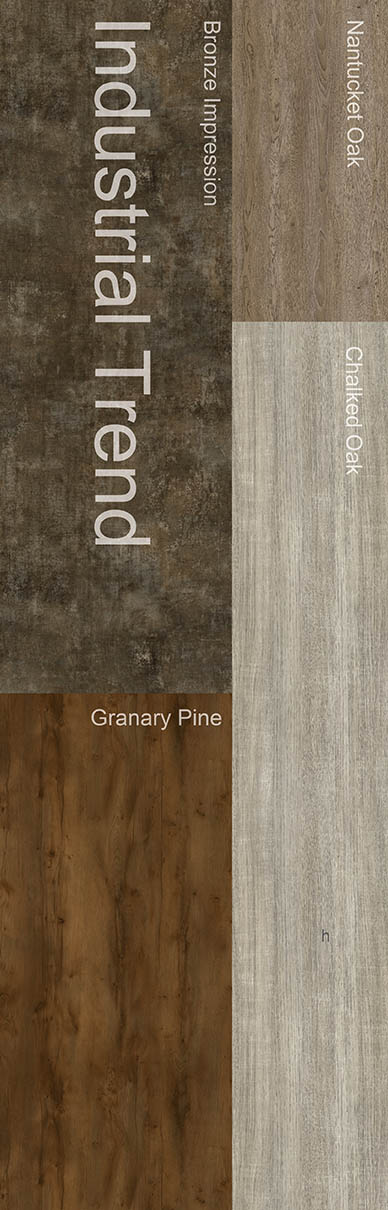

A selection of exquisite and stylish trends for today’s progressive market. View interactive Stonewood Select Overview.

|

|

|

|

|

|

Items discussed in this video are:

|

|

|

Items discussed in this video are:

|

|

|

Items discussed in this video are:

|

|

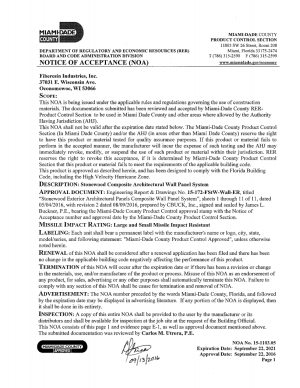

Stonewood is pleased to announce Notice of Acceptance (NOA) from Miami-Dade County for our Composite Architectural Wall Panel System. The NOA facilitates code compliance of the installation and inspection process.

View our product information on the Miami-Dade website.

|

Download our Special Edition |

pdf Printer Friendly Version (510 KB)

When cleaning Stonewood Architectural Panels, use a progressive approach starting with the gentlest cleaning method. It is best to use the least amount of cleaning agents and no scrubbing to remove the debris in order to keep the panel looking beautiful.

Benchmark Recommendation: It is highly recommended to always test clean a small part of the affected area, and once the effectiveness of the procedure has been verified, proceed with the rest of the surface.

Cleaning Progression:

DO NOT USE: Window cleaning sprays, kitchen scouring compounds, or solvents such as acetone, Ethyl Acetate, MEK, nail polish remover, gasoline, benzene, carbon tetrachloride or lacquer thinner. They cleaning agents will cause permanent damage to the surface of the panel.

Repair: There is no approved method to repair the panels. If damaged, they must be replaced.

pdf Printer Friendly Version (4.17 MB)

Please take care not to scratch the surface of the panel during handling, machining and installation. The UV protective surface can be scratched if care is not taken when handing and/or machining the panels. The panels are shipped with protective foam dividers between each panel. This foam barrier should always be used when stacking panels. Panels should be cut using a track saw on a guild rail with a blade designed for cutting aluminum / plastic. Fiberesin recommends the Festool TS 55 REQ Plunge Cut Track Saw and Festool 496307 Aluminum/Plastic saw blade for reference.

There is one A side and one B side to the panels. The A side is meant to face away from the building. Both sides may have the same color/pattern. This does not mean the panel has two sides of equal appearance quality. The B side could have finish or gloss imperfections. Installers are responsible for making sure that the appropriate side is visible. The panels are shipped A side up and there is an identifying sticker on the B side.

Note: The construction buildup of the two sides of the panel is identical. This provides uniform balance and weather/UV protection.

Technical Resources |

|

|

|

|

|||

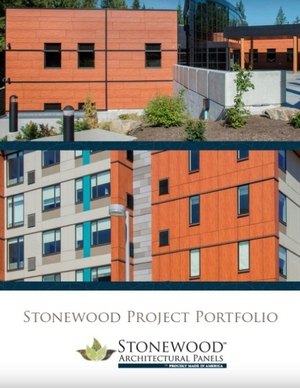

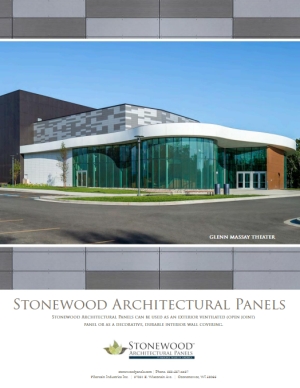

| Stonewood Project Portfolio | Corporate Binder | Exterior Overview | Select Design Offering | |||

|

|

|

|

|||

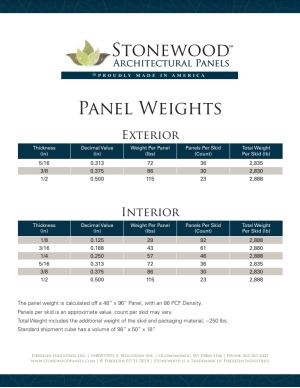

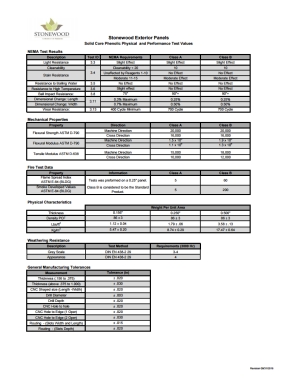

| Standard Design Offering | Product Data Sheet | Panel Weights | Performance Test Values | |||

|

|

|

|

|||

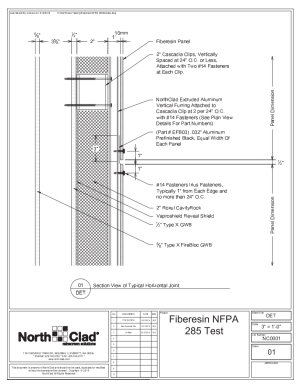

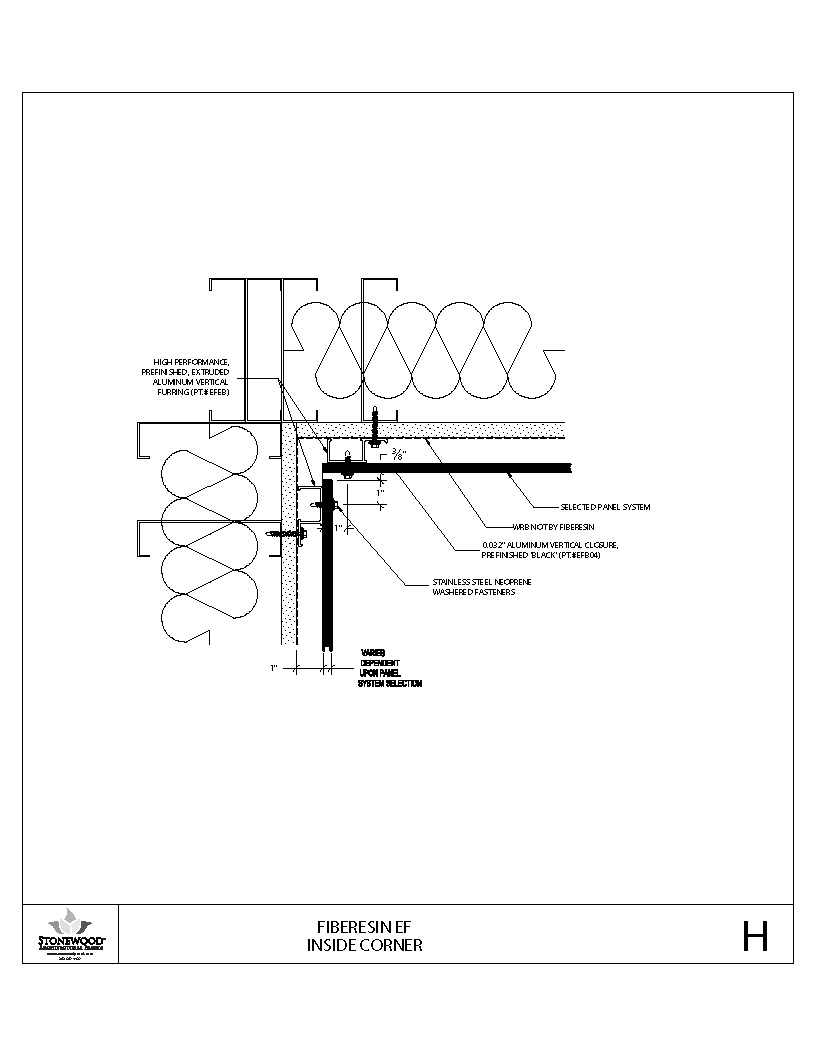

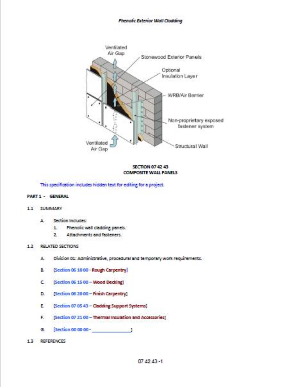

| NFPA 285 Testing | Miami Dade NOA | Complete Details | Specs | |||

|

|

|

|

|||

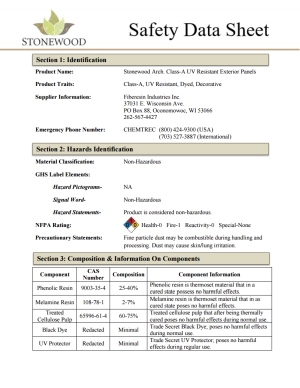

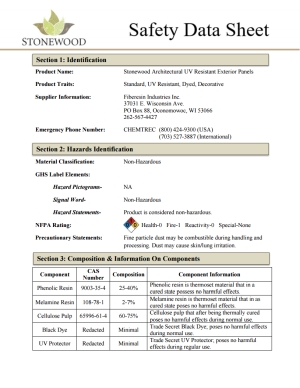

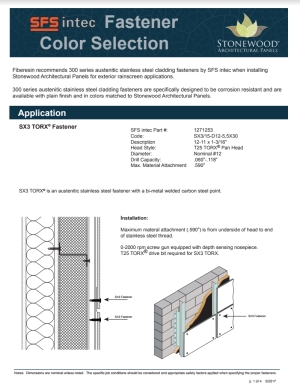

| Class A Fire Grade SDS | Standard Class B SDS | Technical and Installation Guide | Fastener Technical Bulletin | |||

|

|

|

||||

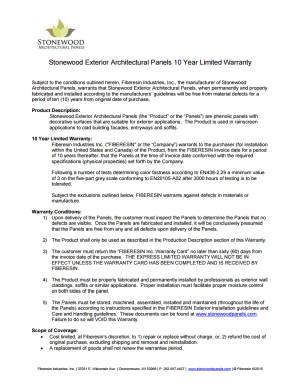

| Cleaning | Warranty | Fastener Technical Bulletin |